It’s been a while, a lot has happened. Time for V8 update #6!

Starting with Klaus Sarembe making the final construction welds on the frame.

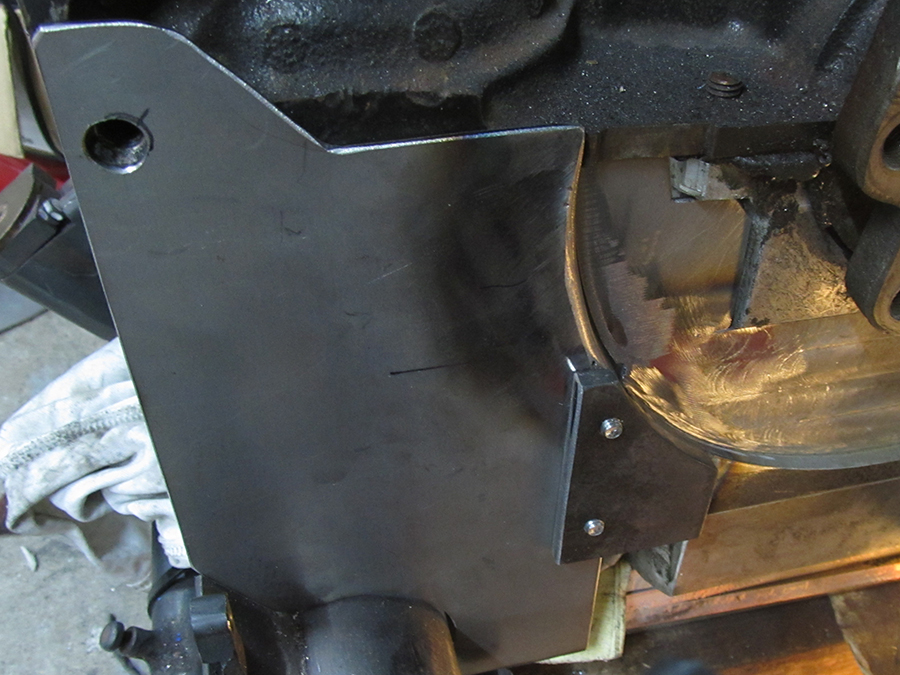

I bolted the frame to the engine and took it to Smit Gloeidienst. For very little money and within a week (thanks guys!) they heated it up with 30°C per hour to about 570°C. When this temperature was reached the oven cooled down with 50°C per hour, to 100°C. This procedure is called ‘annealing treatment’.

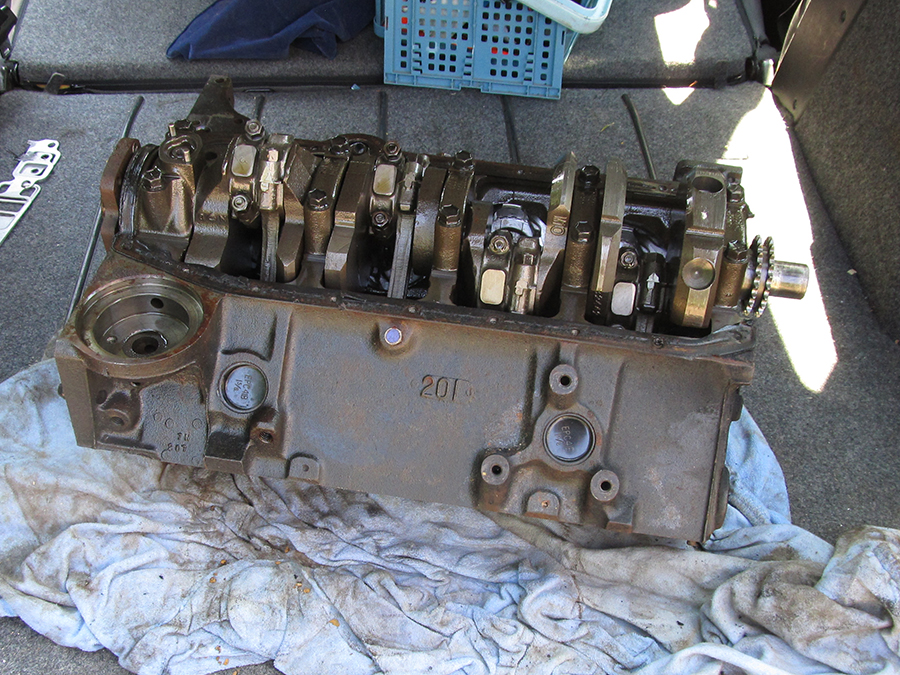

… on the 19th of August 2013 I took the frame and the engine to the RDW at Venlo. The RDW is the one and only official company that does all the licensing of all Dutch vehicles. The procedure to get the bike street legal has two stages: the first is this one, showing the frame and the engine to examine the construction and the origin of the engine. Apart from that I showed them the recording of the first street test, and they liked what they saw.

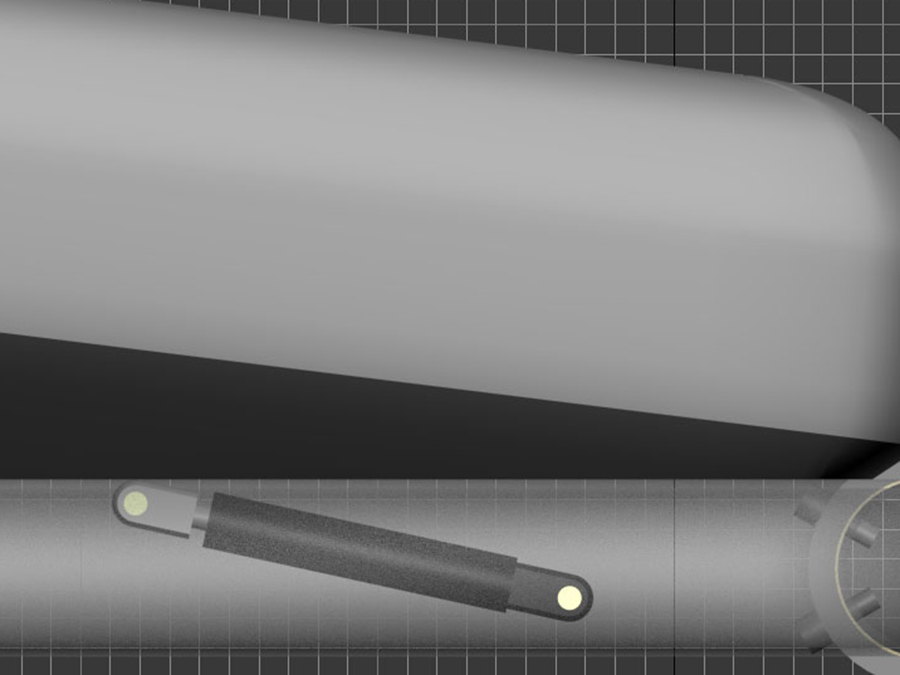

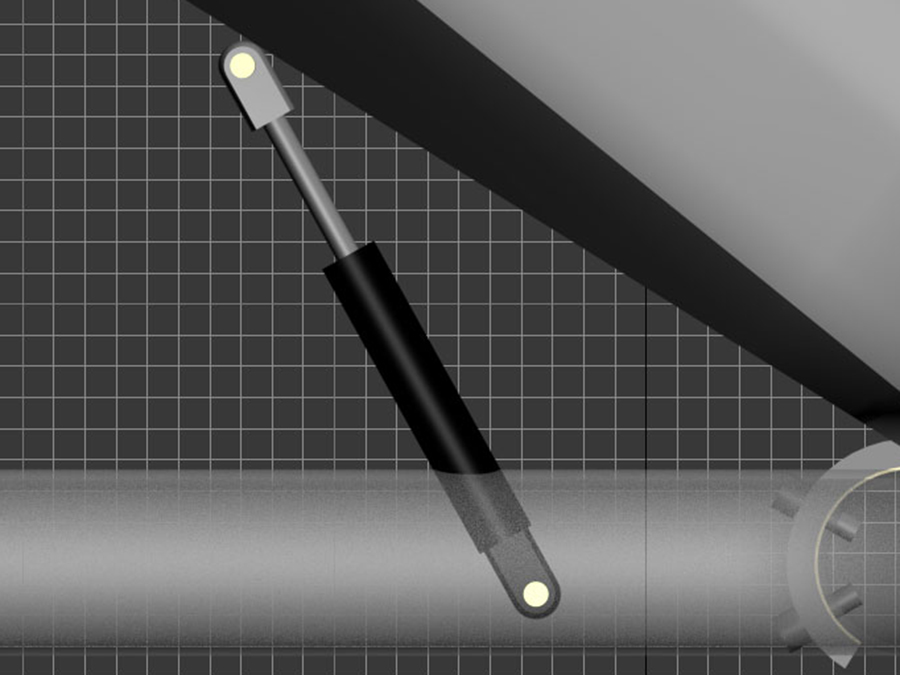

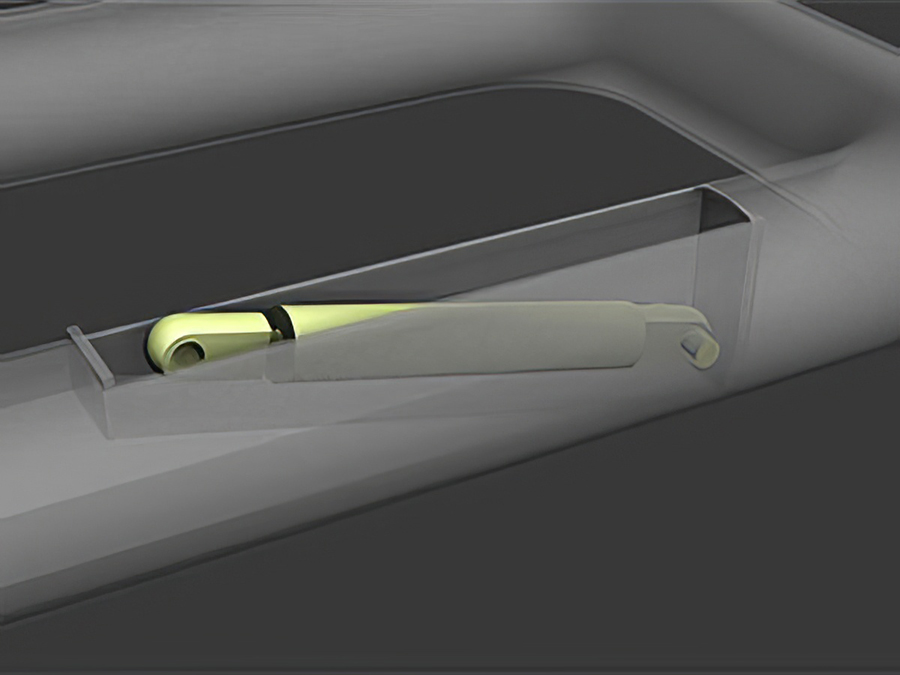

I contacted Springmasters to help me decide which gas springs to use for holding up the tank.

I took the whole wiring loom to Niels. He started optimizing it.

I took the whole wiring loom to Niels. He started optimizing it.

The bike’s paint job is a two stage job as well: one before and one after Lelystad. Kustombart dared to take up the challenge.

Heat, heat, heat, the never ending story. I had the exhaust ceramic coated by S&G Waardenburg. This can cope with high temperature ánd keeps the heat better inside than normal paint.

Heat. Did I tell you about heat already? I hate heat.

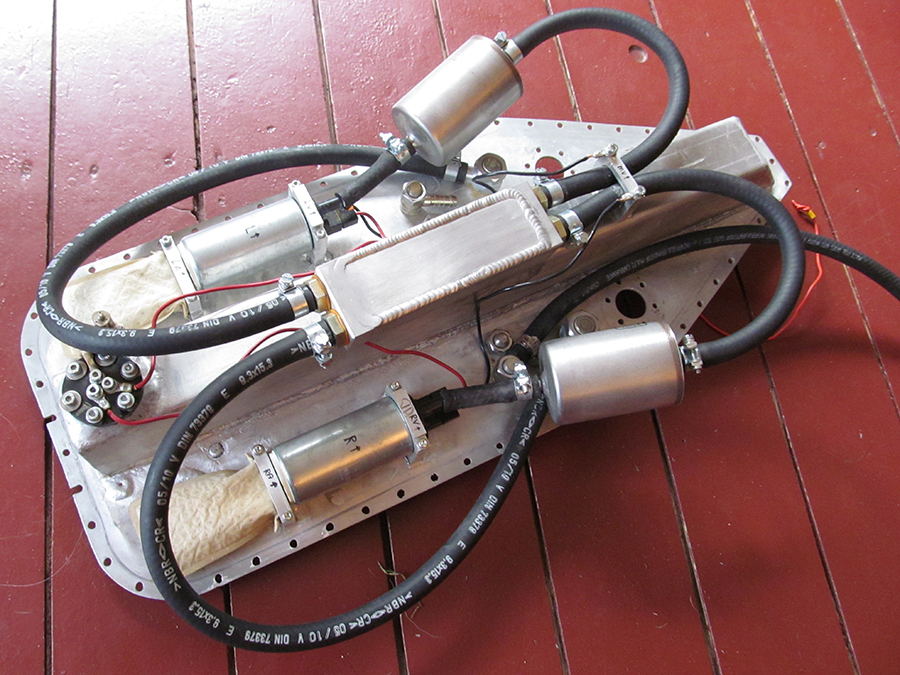

The pre-turbo water-methanol injection system (see previous V8 update) was not sufficient: the droplets were just too big, not atomized enough, to get an efficient cooling of the intake air. So I started designing an alternative new system with an electric high pressure pump.

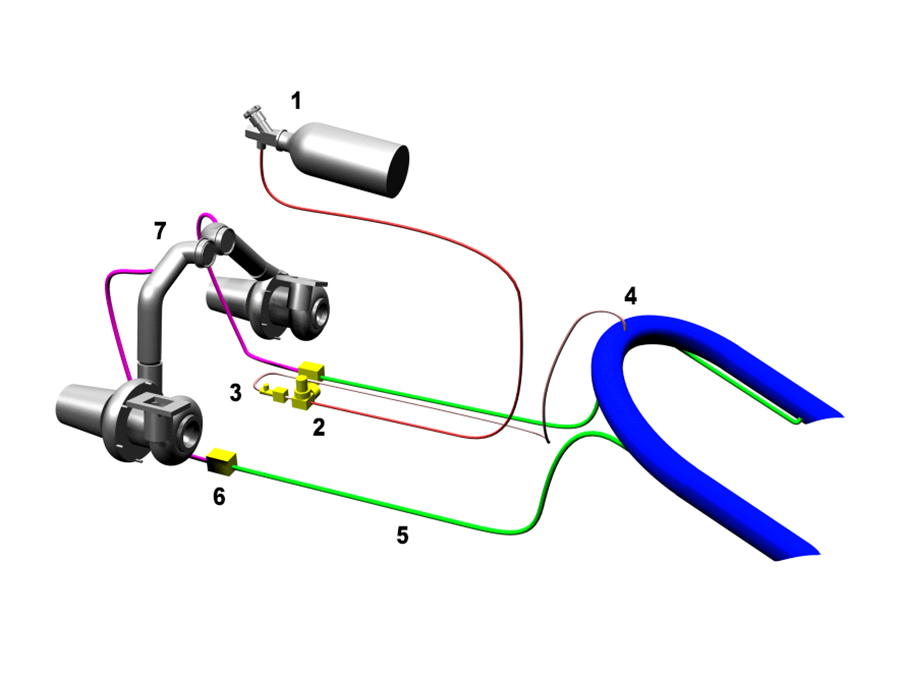

The third (and hopefully final…) system I designed is as follows:

1: I’ll sacrifice one of my NOS bottles for the water-methanol system by filling it with 10 bar of air or nitrogen.

2 and 3: I’ll lead the 10 bar to a pressure regulator with an output op 5.4 bar. Why 5.4 bar? 3.4 bar to atomize the water-methanol pushing against max. 2 bar turbo pressure.

4: The 5.4 bar will put pressure on the water-methanol in my swing arm.

5 and 6: Two hoses at the bottom of the swing arm lead the fluid to the solenoids which are controlled by the motor management system.

7. At full throttle the water-methanol will spray into the intake manifold.

It is a nice theory, and I’m looking forward experimenting with it. But right now it’s not my main concern: at lower revs, the intake temperature isn’t a real issue because the engine has enough power, even without extra cooled intake air.

Peter is an expert on wiring. He helped me installing all the wires for lighting.

“Is that all you’ve done?”

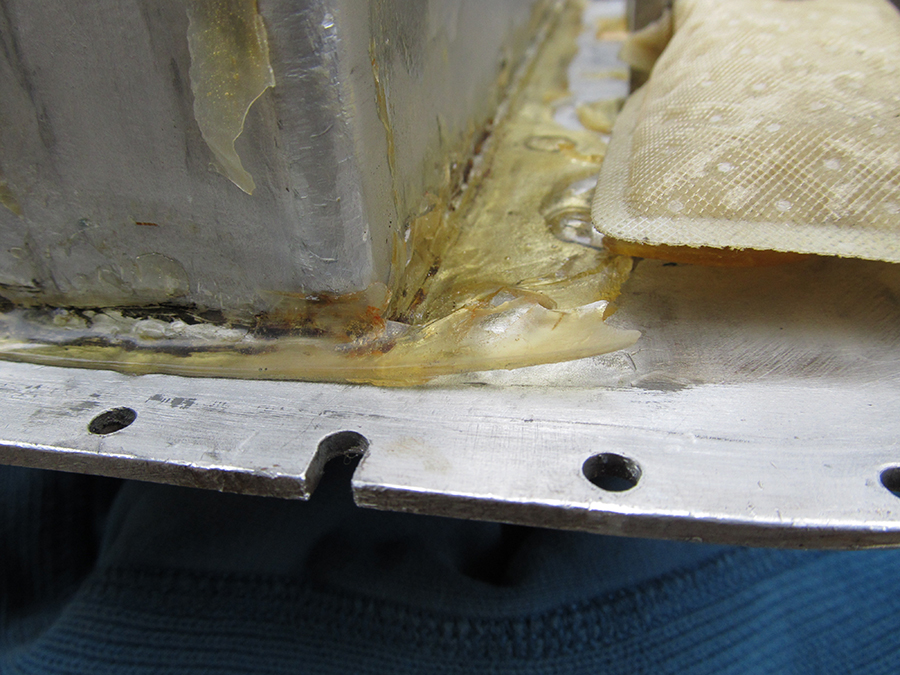

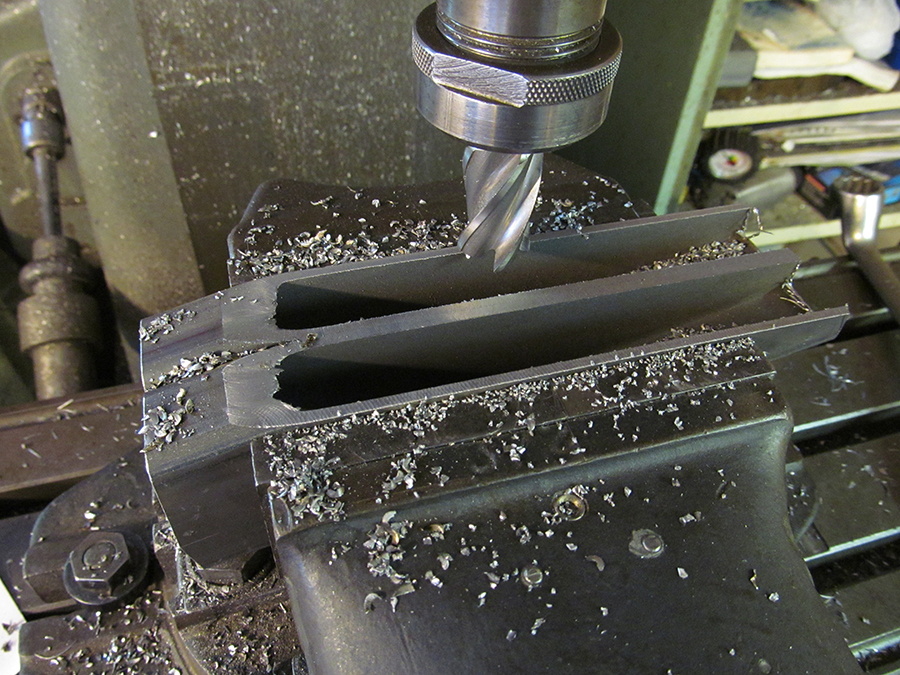

Well no. Hell no! But the more the bike reaches its final looks, the less I can use any pictures without revealing it. To give an impression: new cylinder head covers, installed new master brake and master clutch cylinders, added a overflow tank for the cooling system, replaced the clutch release bearing and the clutch pilot bushing, made new heat shields for the exhaust, improved the side stand, finetuned the gear drive, improved the rear braking system and the crankcase breather.

What’s next? Next month a final (I hope) Dyno test, a final (I hope) street test, clearing lots of small (I hope) problems. And then: Lelystad, here we come!

To be continued … here.