This website, moreismore.bike, came online in January 2015. March 2024, I converted the first 12 reports, from September 2002 to November 2022, from Adobe Muse to WordPress.

The content is virtually unchanged; In this update, however, the photos can be enlarged by clicking on them, and the content is no longer ‘blurred’; the bike has gone public in November 2022, so blurring is no longer necessary.

I have scaled up some images with AI, of which I couldn’t find the originals.

Enjoy reading.

Every now and then I’m asked about the progress of my V8 project; so did Stefan Reekers in my guestbook. Not a very strange question considering I’m busy for more than five years. On the other hand I’m not too keen on providing any information so I choose this compromise: an update, a glimpse behind the scenes, but not a overall picture. Well, I suppose it’s better than nothing …

September 2002, shortly after finishing the CBX, I decided building a motorcycle based on a V8 engine; in fact a very natural sequel after the sixcylinder CBX. As the Chevrolet is the undisputed godfather of V8 I had no doubt about the choice of engine.

Koen Roemaat, a friend of mine since ages, spontaneously lended me a Chevy smallblock for indefinite time. Lucky for me: it’s still in my garage and serves a great job as mock-up.

Of course I visited ‘rival’ Boss Hoss, situated in Venlo (NL). The salesman certainly did not get the point: “Why build a V8 if you can buy one here?” Well, that’s easy to answer: 1. what they sell does not appeal to me at all (lazy chopper-look, too massive, too much chrome, too much plastic), 2. buying = boring, and 3. €50.000 Euro is a lot of money.

I met Theo Verbeet (r) who ownes a V8 Motorcycles-bike. He was quite enthusiastic about it, although the frame revealed a lot of sloppy construction errors. Is that why this company doesn’t exist anymore…?

On the left you see Klaus Sarembe: friend, skilled craftsman (he does almost all the welding), dragracer and my most important compagnon during this project. Building a bike is 80% debating and 20% actual constructing; so it’s important you get along really well.

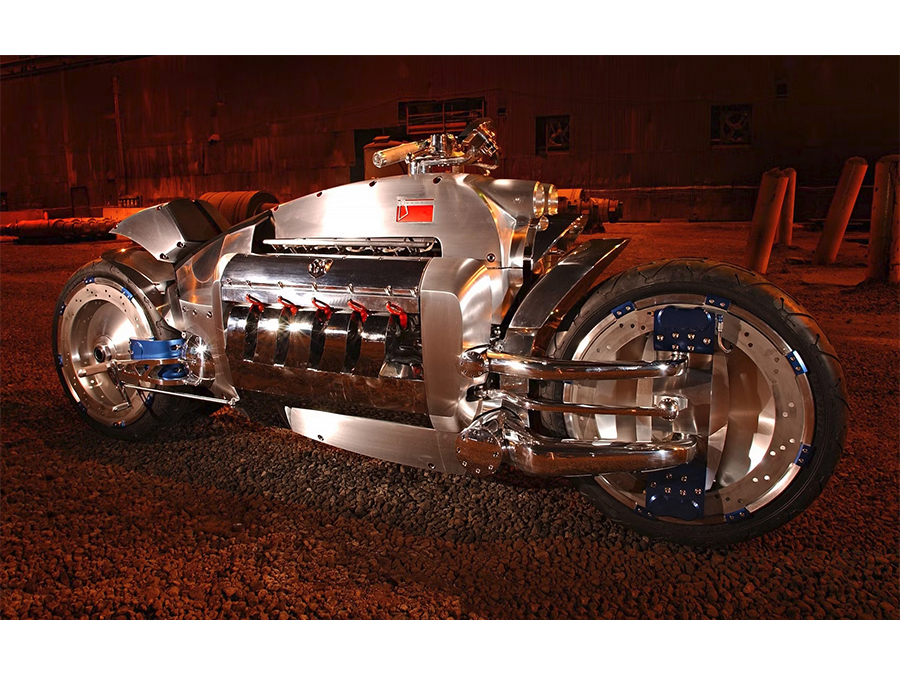

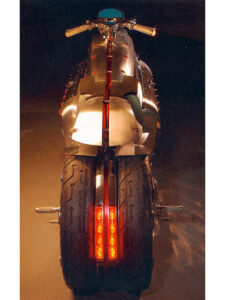

Is a V8 engine always doomed to degrade in a chopper frame? No, proven by this beast based om a Dodge Viper V10: the concept-car named Tomahawk. Fantastic design, despite the fact that its four wheels technically makes it a car.

Futuristic, innovative, incredible loud and not allowed on the public highway. Nine replica’s were built, each kosting $555.000,-. Not too much money for us Europeans, considering the low dollar exchange rate ;-)

Futuristic, innovative, incredible loud and not allowed on the public highway. Nine replica’s were built, each kosting $555.000,-. Not too much money for us Europeans, considering the low dollar exchange rate ;-)

For me it’s very important to get this bike legalized: it’s no use to build a trailerbike. This one, like the CBX, must make its miles on the road. And, no less important: make its quartermiles on the dragstrip.

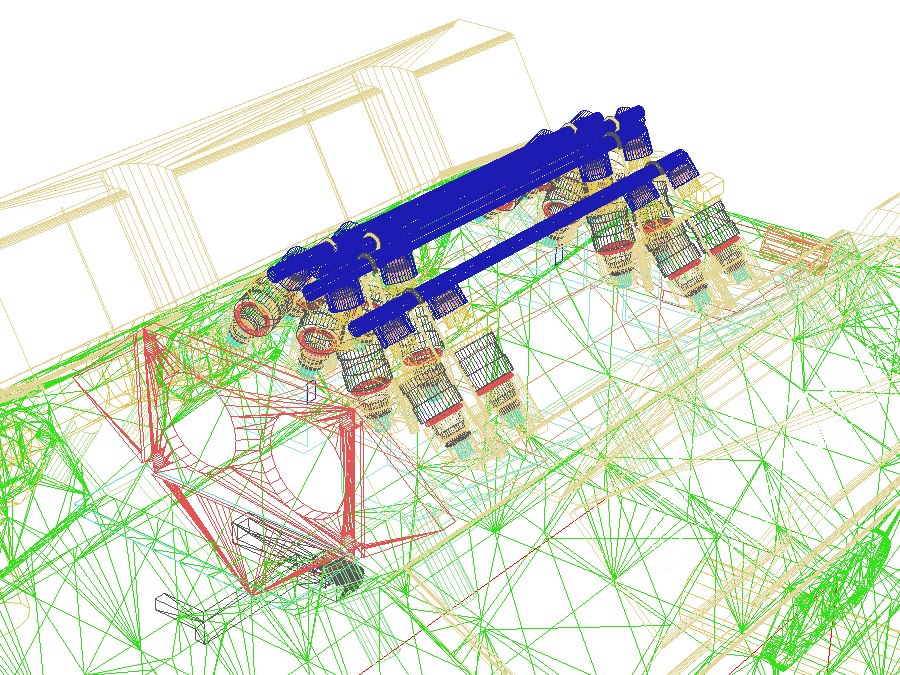

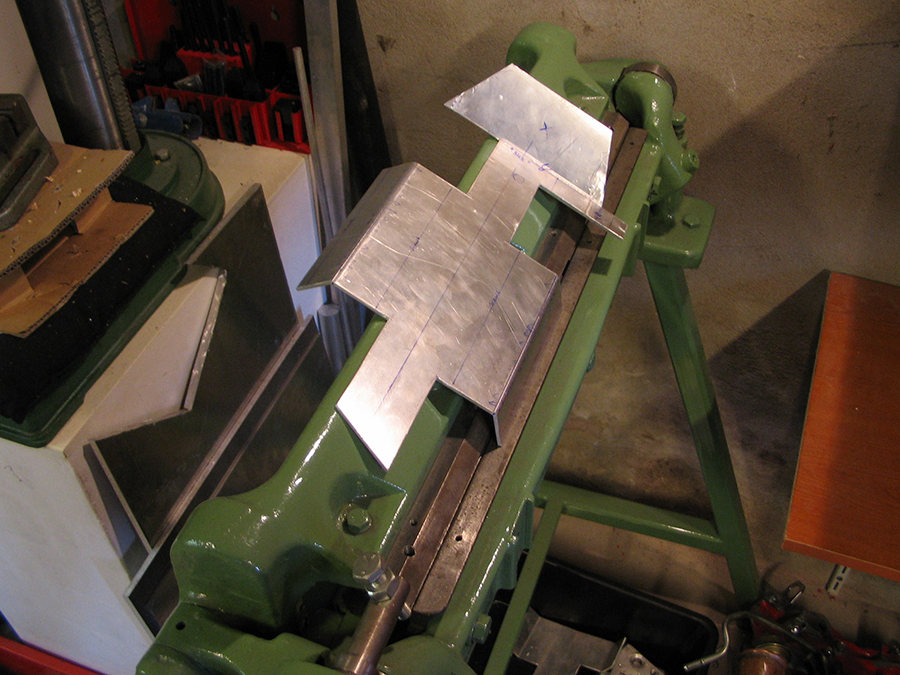

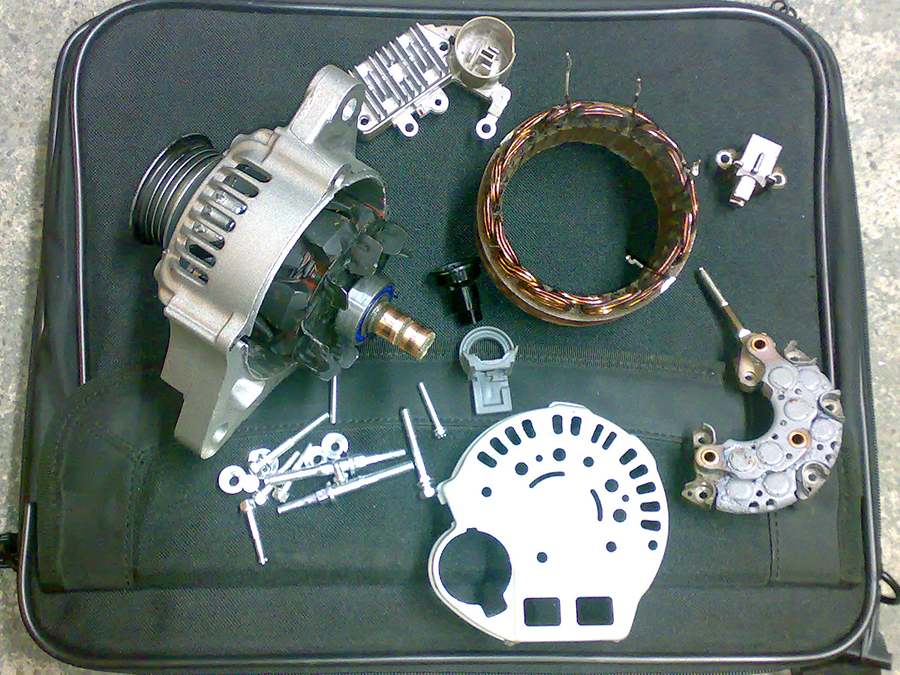

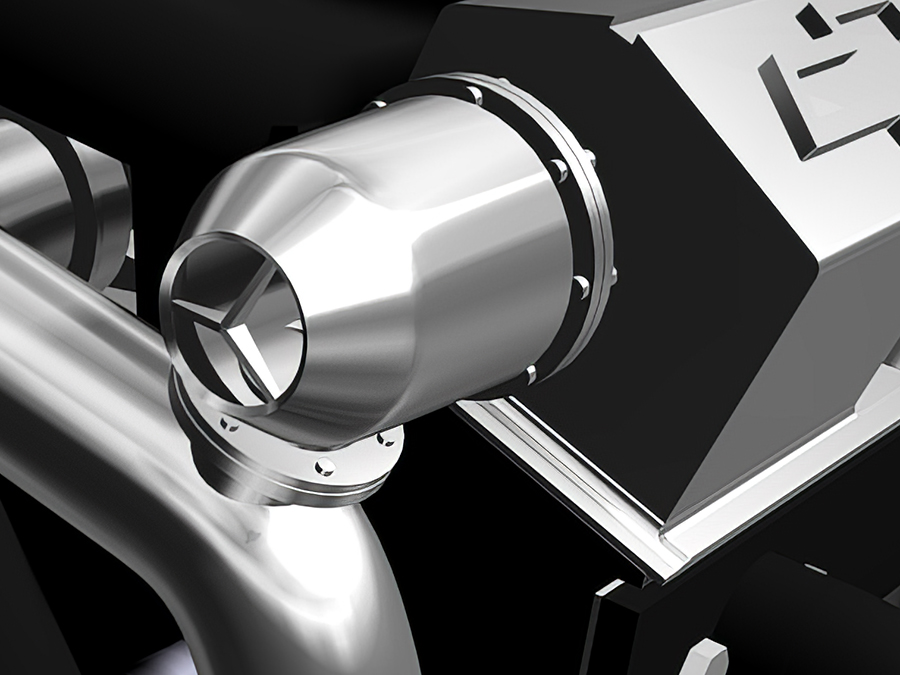

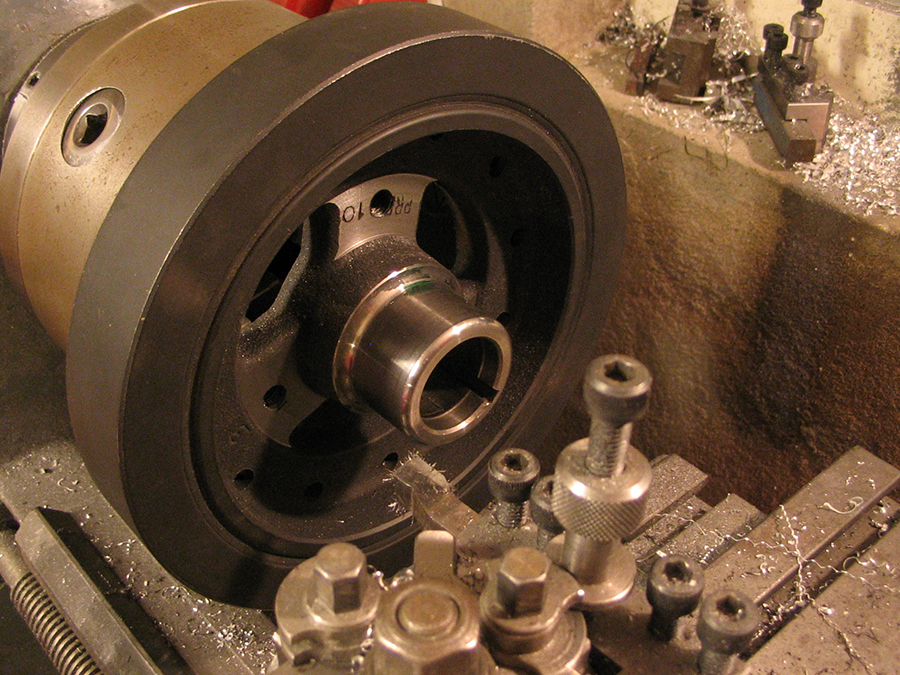

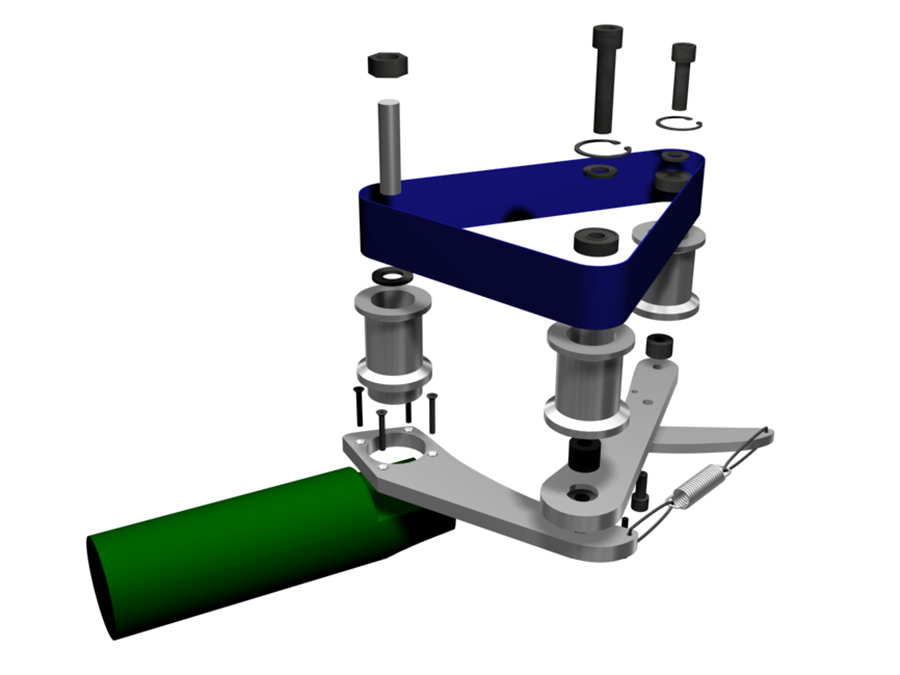

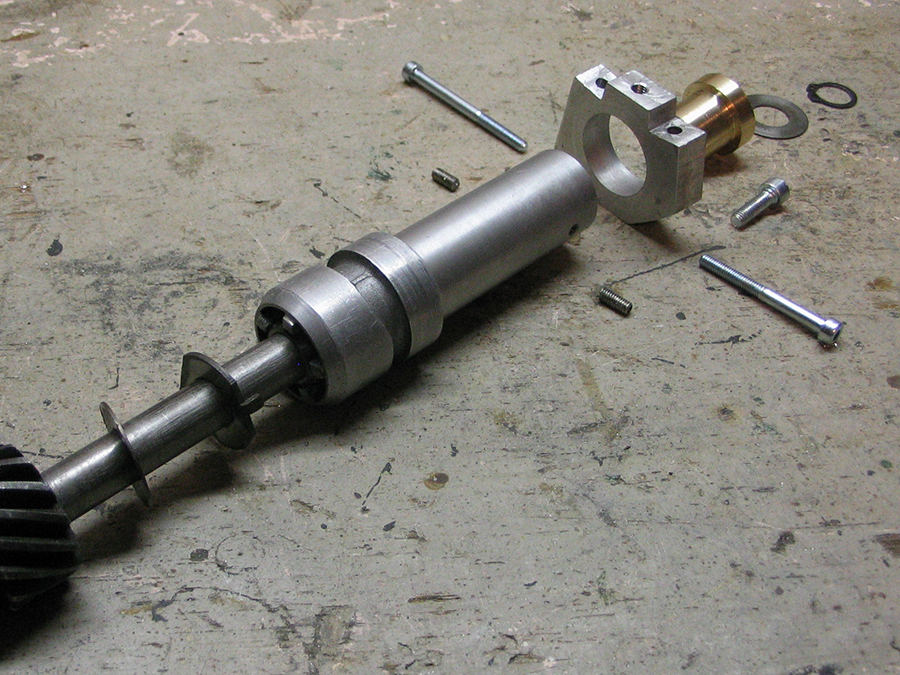

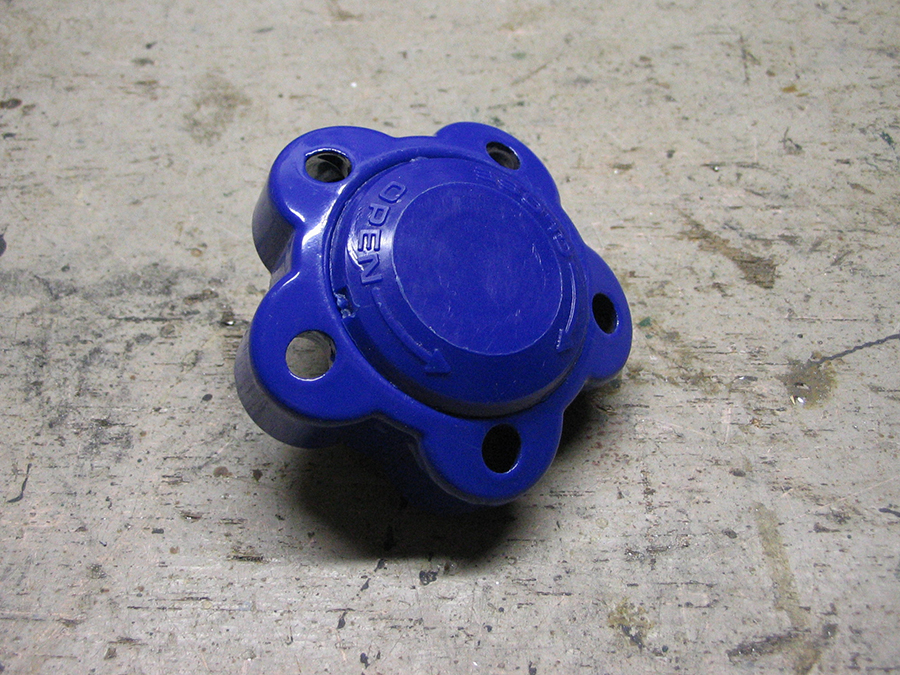

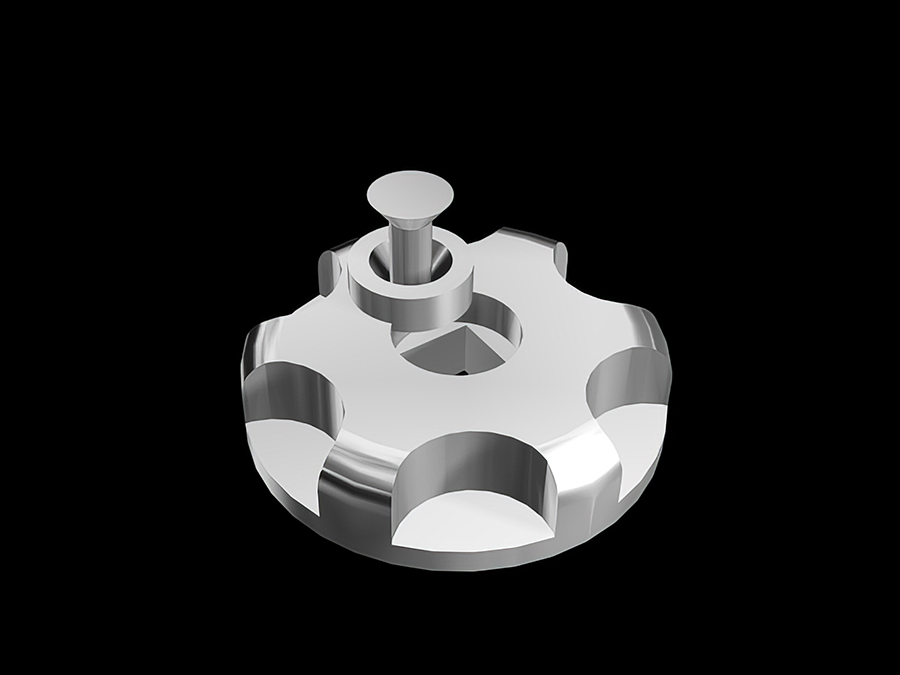

Like the CBX the design started in the computer: I modelled my body in a 3D program and did the same with the Chevy engine. My design evolved step by step, not into a chopper or cruiser, but rather into a streetfighter or dragracer. Such a 3D program provides photorealistic pictures and offers great help for the physical realization (milling, lathing).

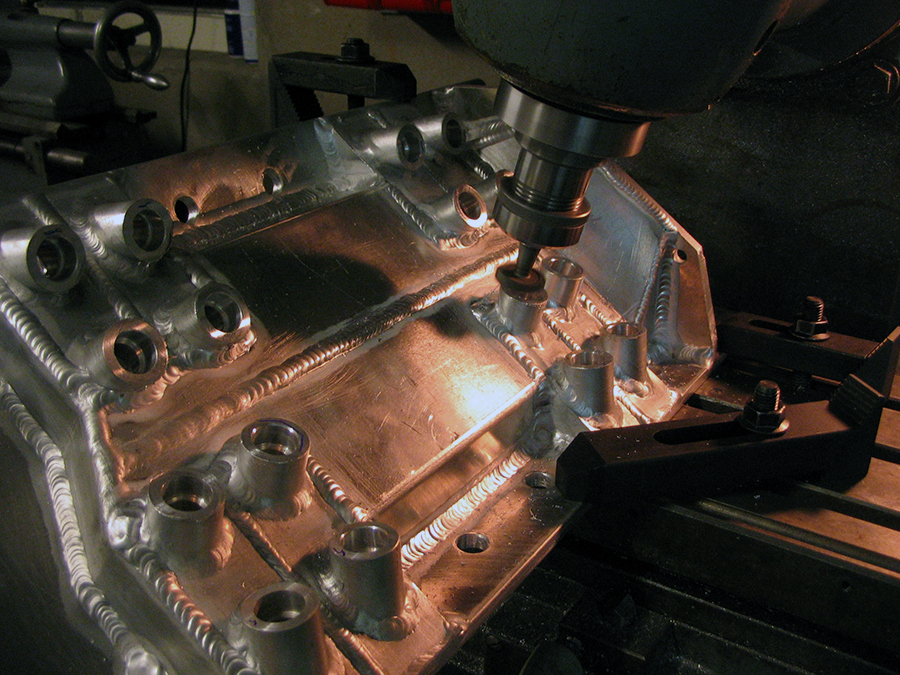

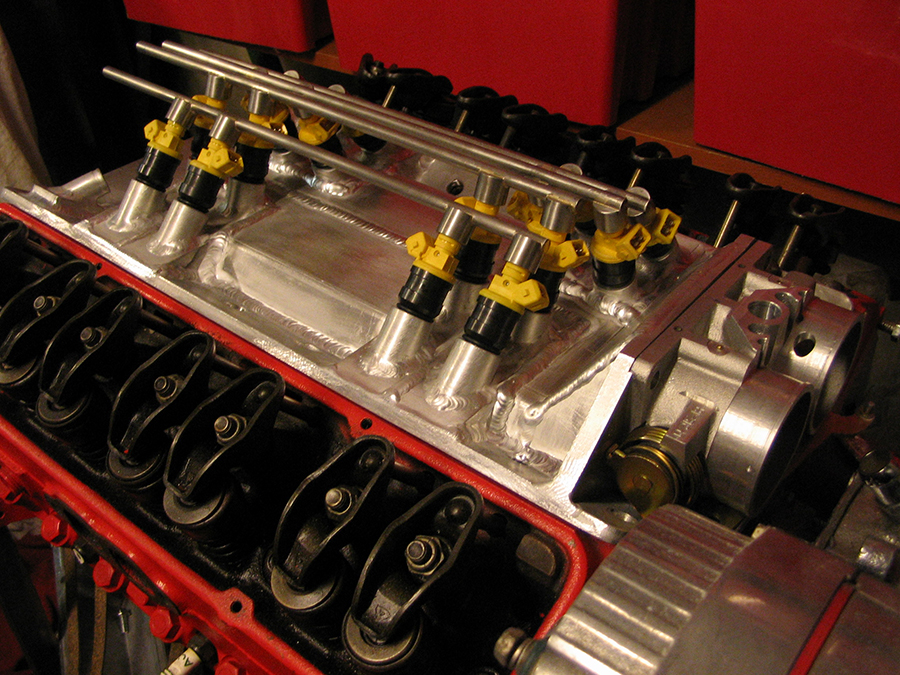

An airfilter was planned on top of this voluminous intake manifold and huge carb. My design did not include a monstrous tank with a tower piling through, so I had to make a drastic change: eventually I decided to sell both Edelbrocks and build myself an fuel injection system. This would be far more compact and offers some nice new opportunities like putting a turbo on the bike … or even two turbos … and injecting NOS. If you’re building bigger, why not going brutal?

I met Niels Saarloos, bikebuilder since kindergarten and expert motormanagement and injection systems. He offered me his help.

I met Niels Saarloos, bikebuilder since kindergarten and expert motormanagement and injection systems. He offered me his help.

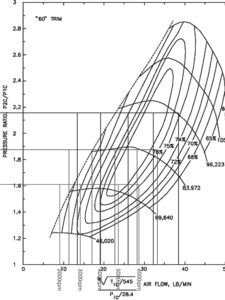

The wonderful world of turbos was unknown to me until then; I studied books and the internet to get familiar with this matter. Fortunately Klaus and Niels were experienced, and I got some advice from Pjotr Bierman at C&P USA Parts.

The wonderful world of turbos was unknown to me until then; I studied books and the internet to get familiar with this matter. Fortunately Klaus and Niels were experienced, and I got some advice from Pjotr Bierman at C&P USA Parts.

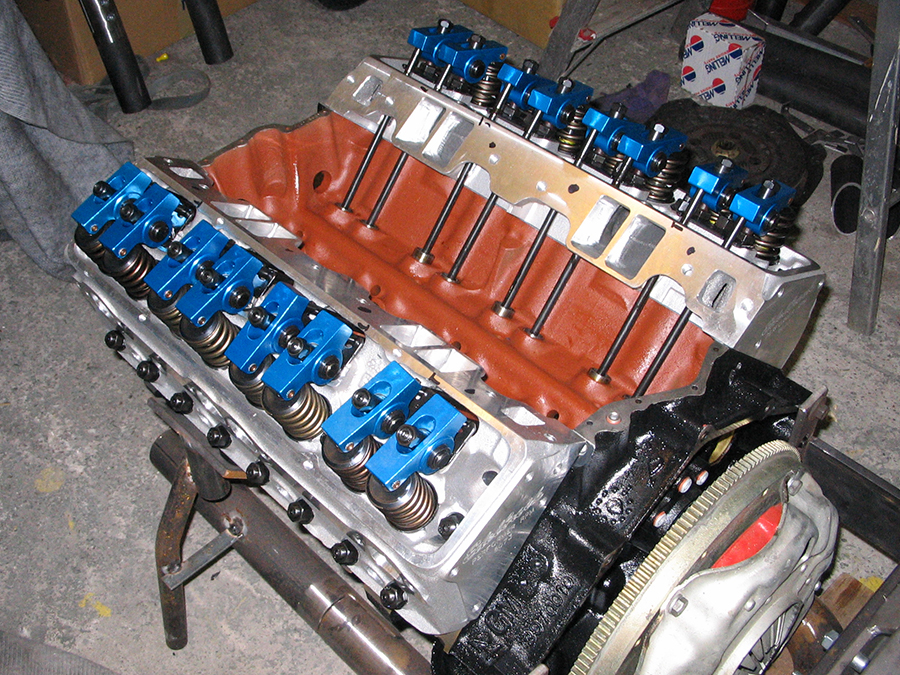

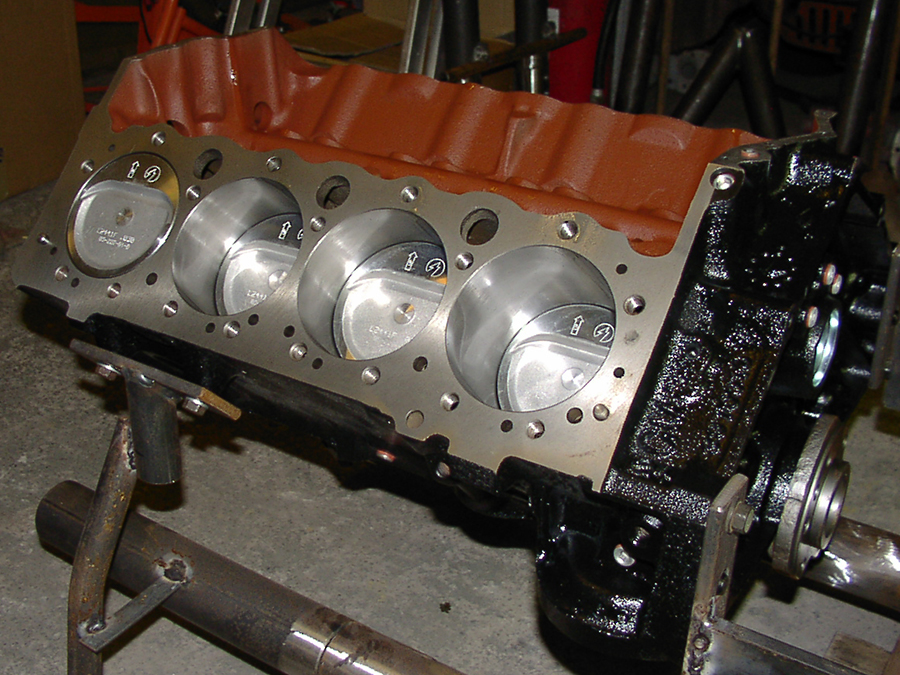

My choice had even more consequences: a standard two-bolt Chevy engine would survive the violence of turbos and NOS for just a few seconds, and those extras are not only for showing off. After consulting Ronnie Spijker and John Bakker a company called PAW in the States built me a brand new high performance four-bolt engine. I keep the exact specs a secret, but believe me: this engine can take some beating.

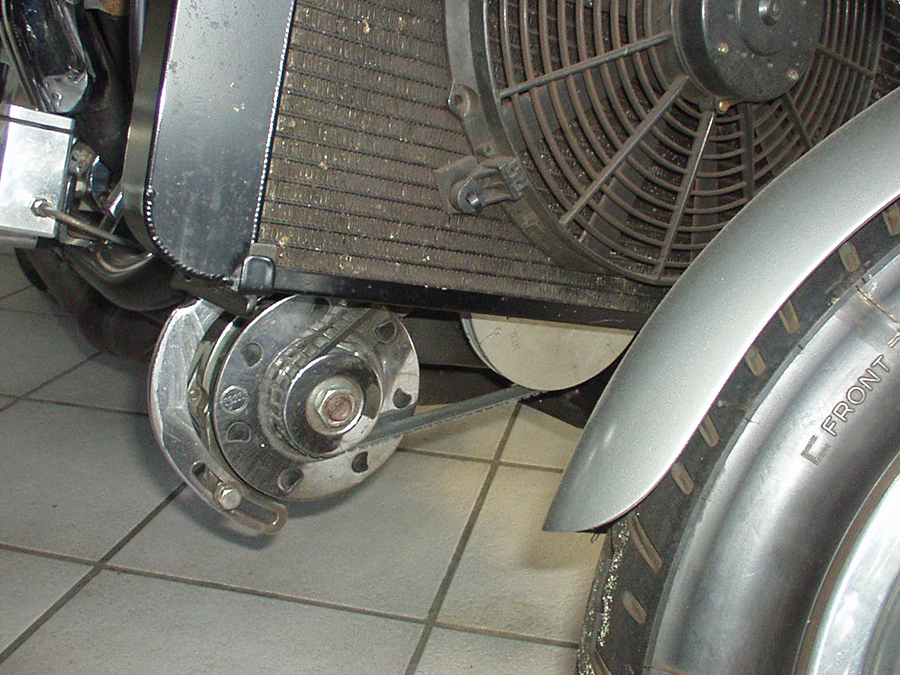

Cooling the engine is a chapter of its own. I found Chris Jansen, inspired owner of Hartgers Radiateuren on the internet. His site shows a button called ‘maatwerk’ (made-to-measure) and that’s what it’s all about. After some consultations and calculations I started designing the radiator. I made a mock-up from polystyrene foam, he made one from wood and finally an aluminum one. You can see the result on his site at the button ‘maatwerk’ (‘custom’); where else?

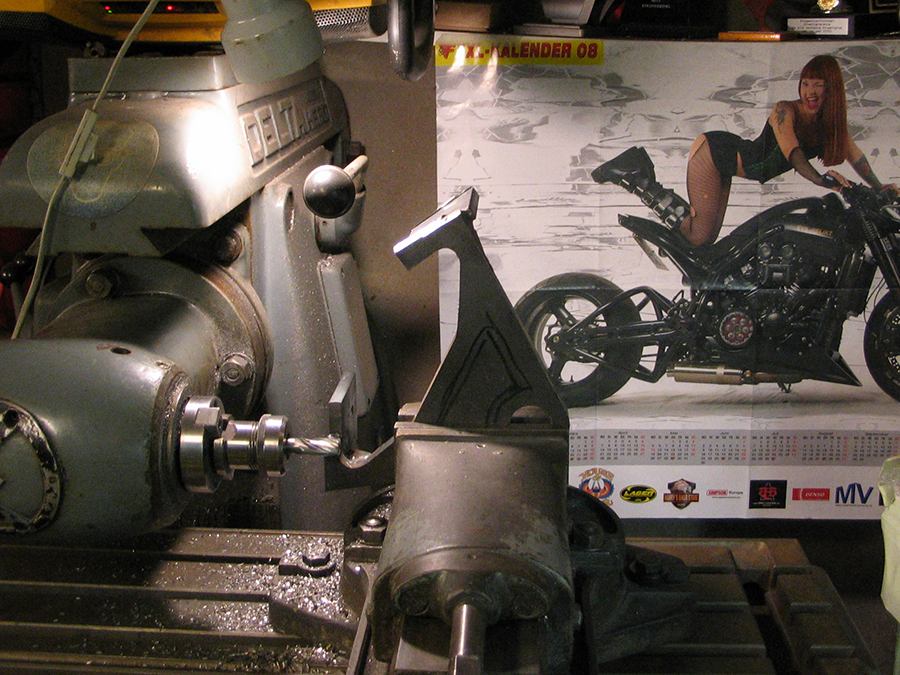

To mount it I had to construct a steel bracket.

On the background you see my favorite bike of 2007: Evil Relikt by Marc Schusters.

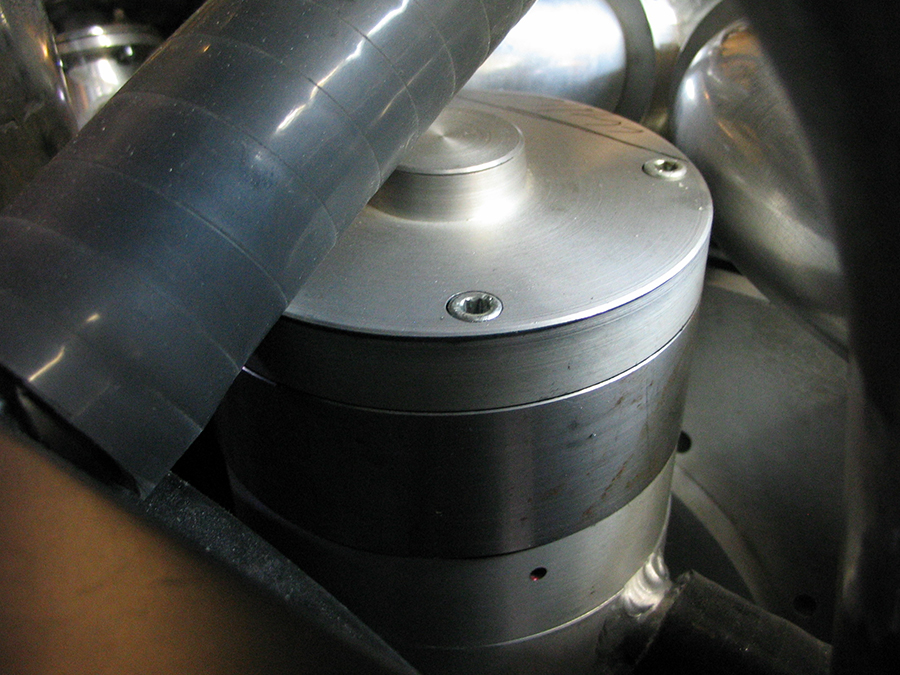

After consulting Rob Westenberg at SO Products I ordered their strongest monoshock. Which, of course, had to be modified.

Marc Michels helped me to mount two TiAL wastegates.

I contacted mr. Huis in ’t Veld and Richard at Tubex. They supplied the loose parts while it was my job to to saw, grind and build the exhaust.

In the summer of 2006 I met Eddie Duine during Nitrolympics at Hockenheim (D). He repaired the exhaust from the CBX and offered to do some welding of the V8’s exhaust. So he did, and again he did a good job.

The exhaust will, at any time, be enamel coated by Hans Pieper at ColorPipes.

Have I forgotten to mention anyone? Yes: Roelf de Haan at EPS gave some good advice about the engine and exhaust manifold, Marco Kleijssen clarified troubles with the oilpump. Together with company Holl I fight the War on Threads like UNC, UNF, Metric and NPT (just to name a few), companies like Eriks give a huge discount on their products to support this project. In the (near?) future Frank Fijlstra will do the paintjob, Lothar Obst will take care of the seat.

Talking about ’the near future’: I don’t have a definite timetable because it’s very hard to predict what (set backs?) awaits me. My most upbeat prophecy: ridable and M.O.T.in 2008, paintjob and finishing in 2009, on the road in 2009. Supposing it’ll be 2010 it would have taken 8 years. V8 … 8 years … 8 in Italian is ‘Otto’ … would be quite logical, wouldn’t it?

Update November 21st 2009: read the continuing story on this bike build here.