Welcome to update 12, almost three years (!) after the previous one. Main cause of this delay: the corona crisis.

Welcome to update 12, almost three years (!) after the previous one. Main cause of this delay: the corona crisis.

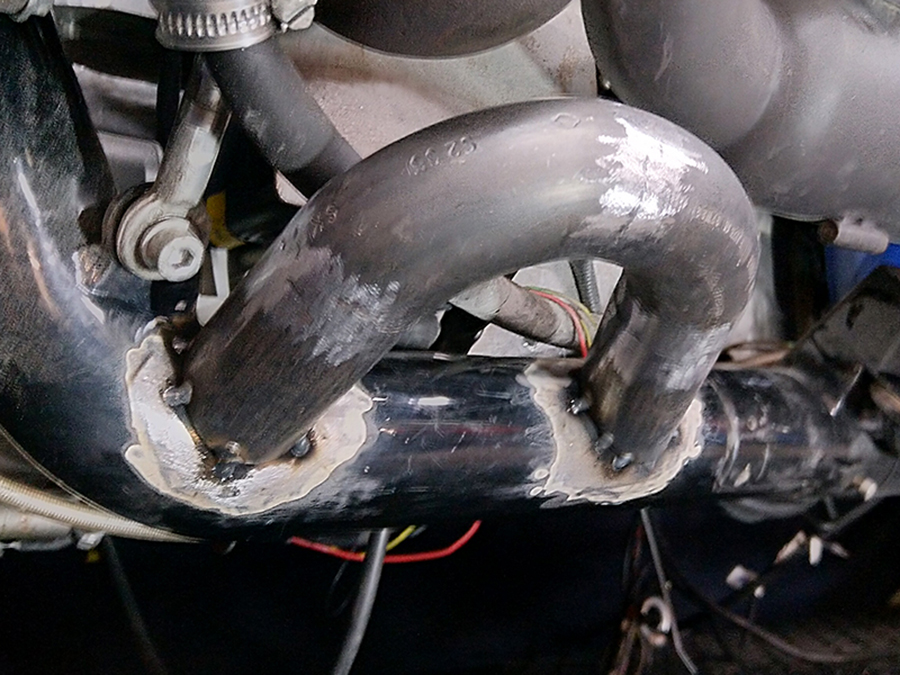

I ended up in update 11 with a rather dangerous backfire. And with the happy observation that we were still alive, and that the engine still was intact, quite important as well.

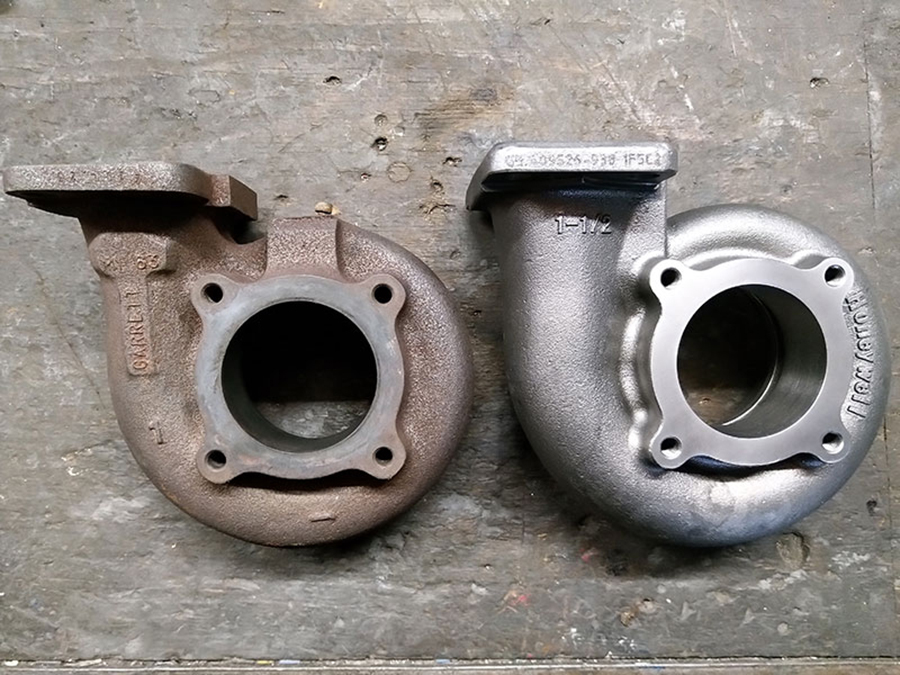

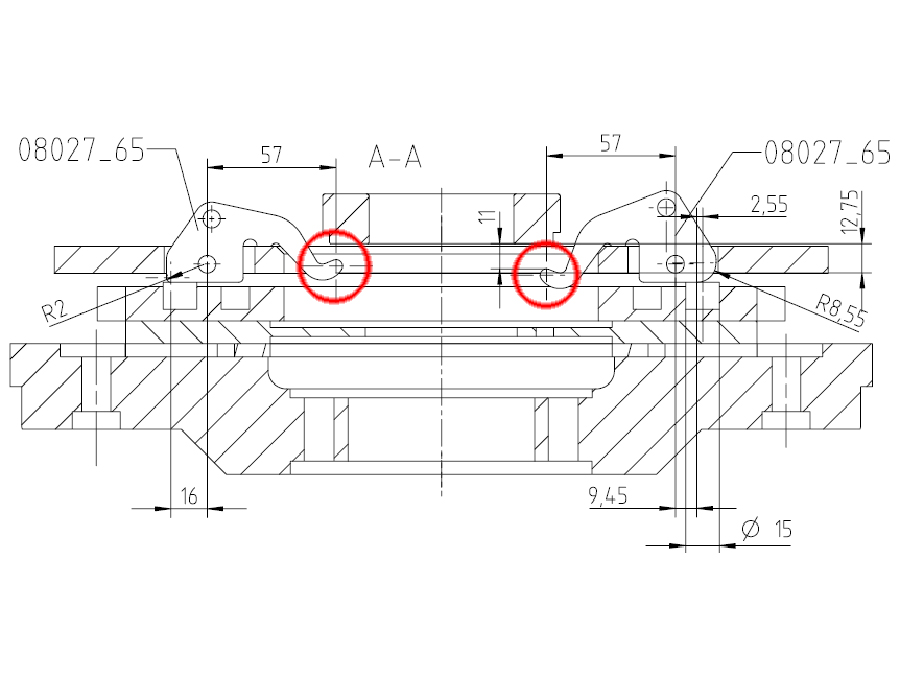

To increase the flow of the exhausts, we looked for larger turbine housings for the turbos.

Both turbine housings (left) have been enlarged from .63 to .82 A/R (right). The larger passage causes greater flow and therefore less pressure in the exhaust manifold.

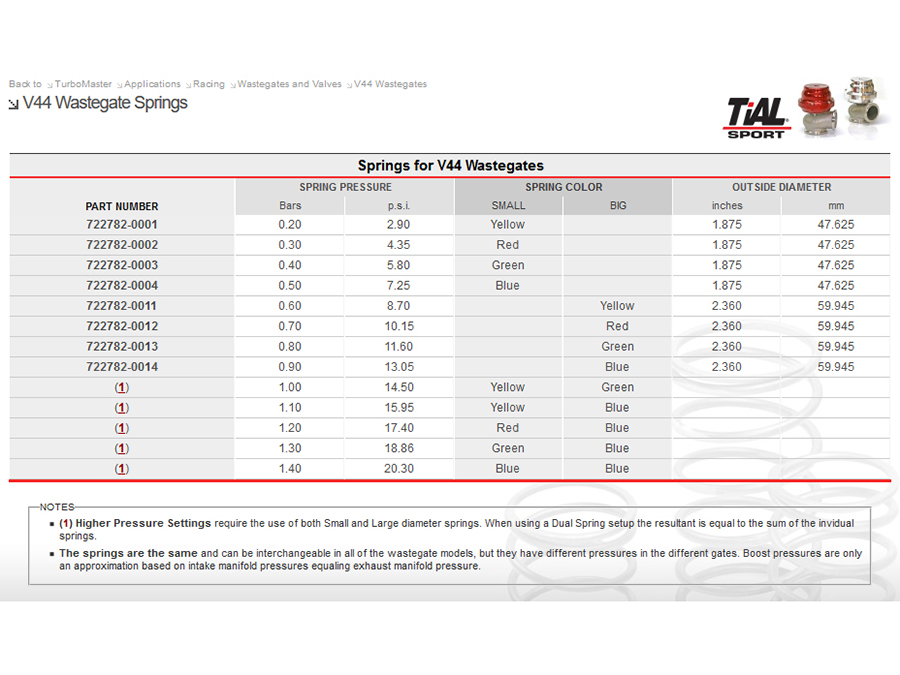

On the left the narrow 0.2 bar spring, replaced by the narrow 0.5 bar spring on the right.

On the left the narrow 0.2 bar spring, replaced by the narrow 0.5 bar spring on the right.

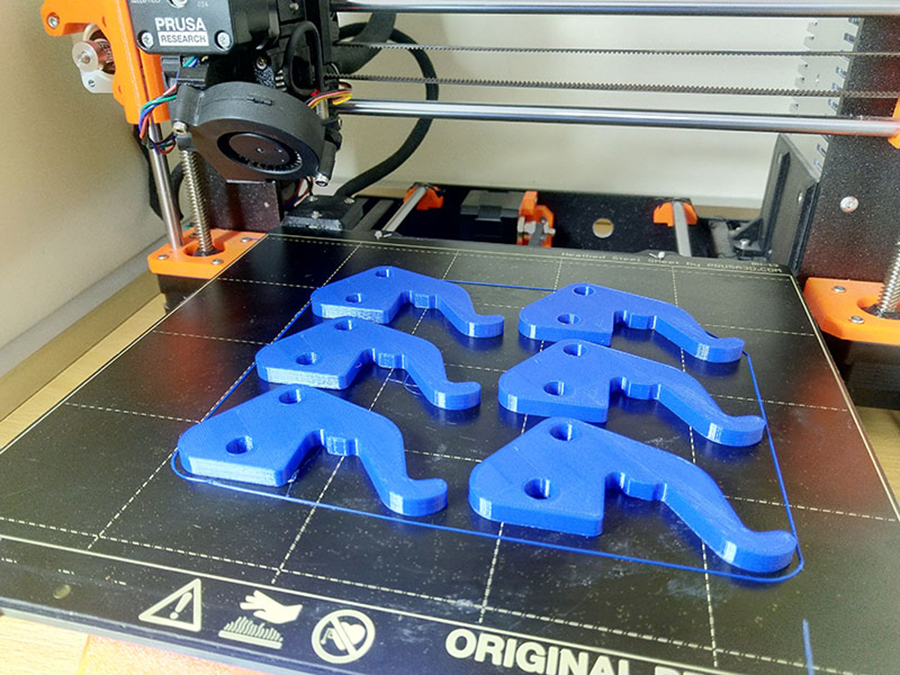

To be able to test even better, I also ordered two wide 0.9 bar springs. Combining wide and narrow springs allows us to test different wastegate configurations:

0.2 bar: yellow narrow;

0.5 bar: blue narrow;

0.9 bar: blue wide;

1.1 bar: yellow narrow + blue wide;

1.4 bar: blue narrow + blue wide.

In May, together with Erwin, I took a trip to Marcel from corsa-novatuning.nl, because he could fill my NOS bottle.

In May, together with Erwin, I took a trip to Marcel from corsa-novatuning.nl, because he could fill my NOS bottle.

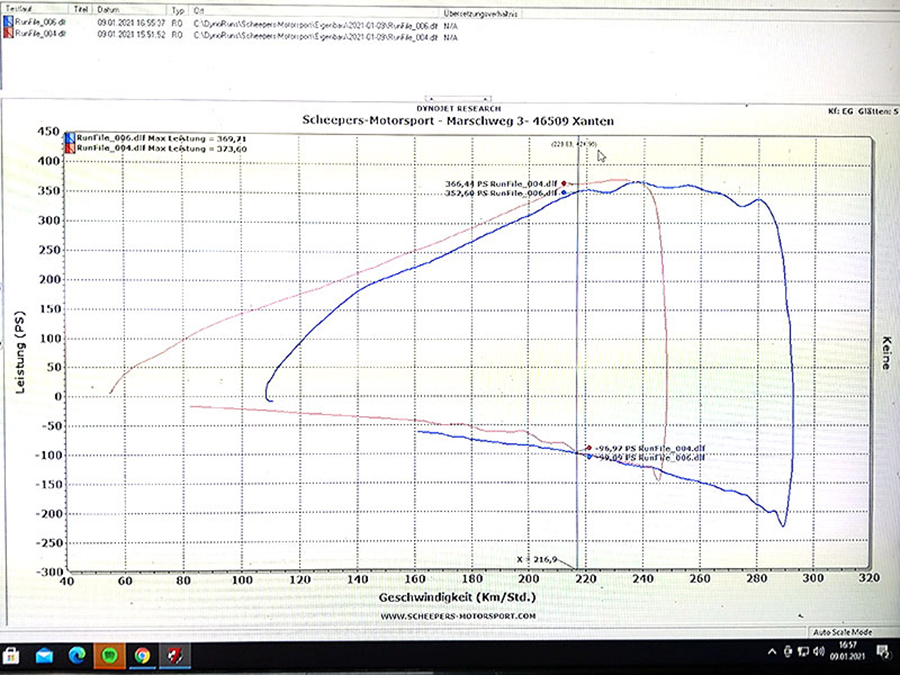

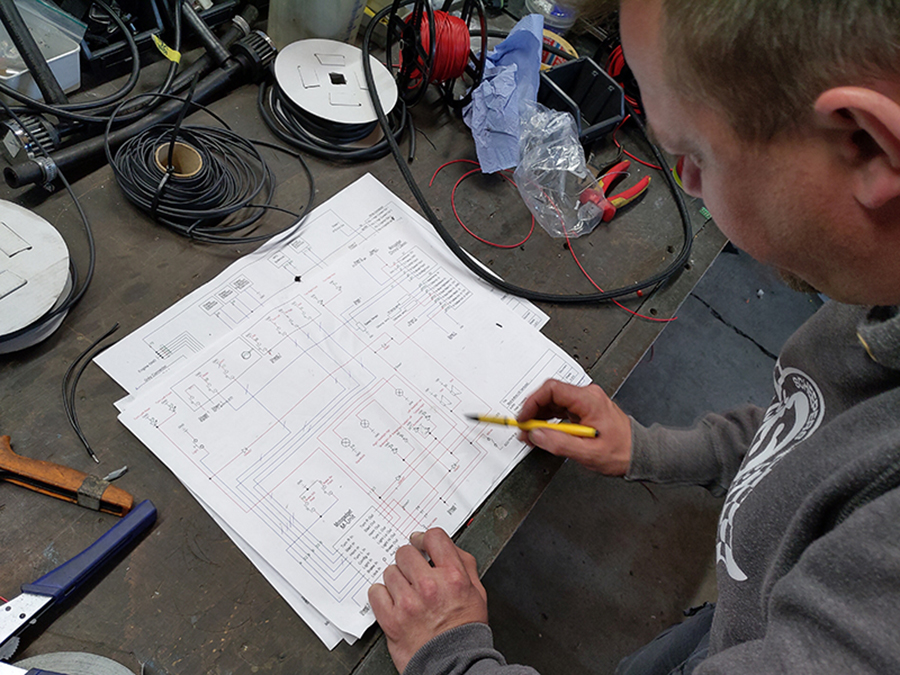

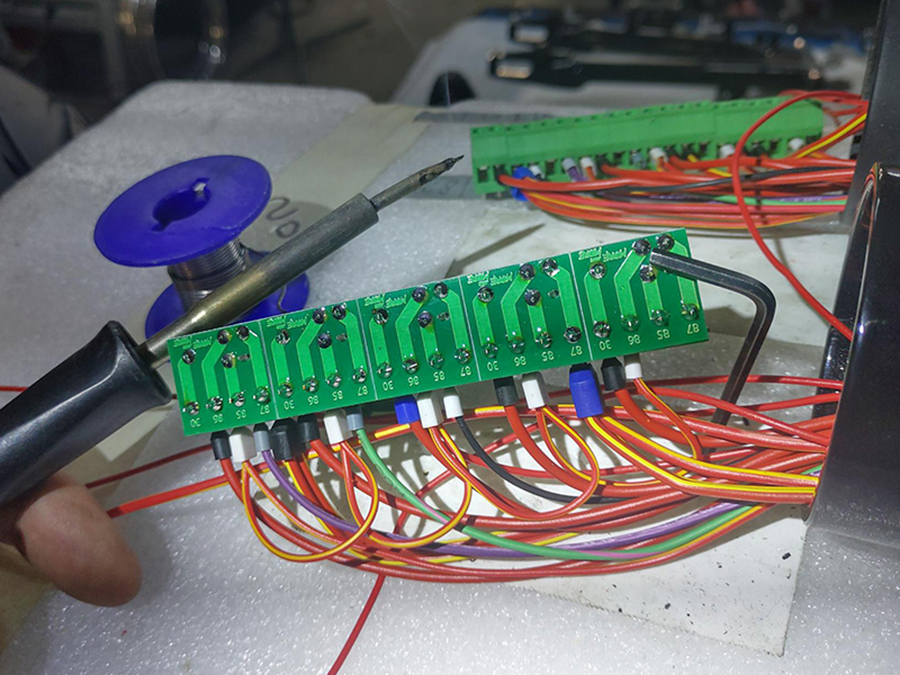

Between the lockdowns, Peter Scheepers and I prepared hardware and software for NOS.

Between the lockdowns, Peter Scheepers and I prepared hardware and software for NOS.

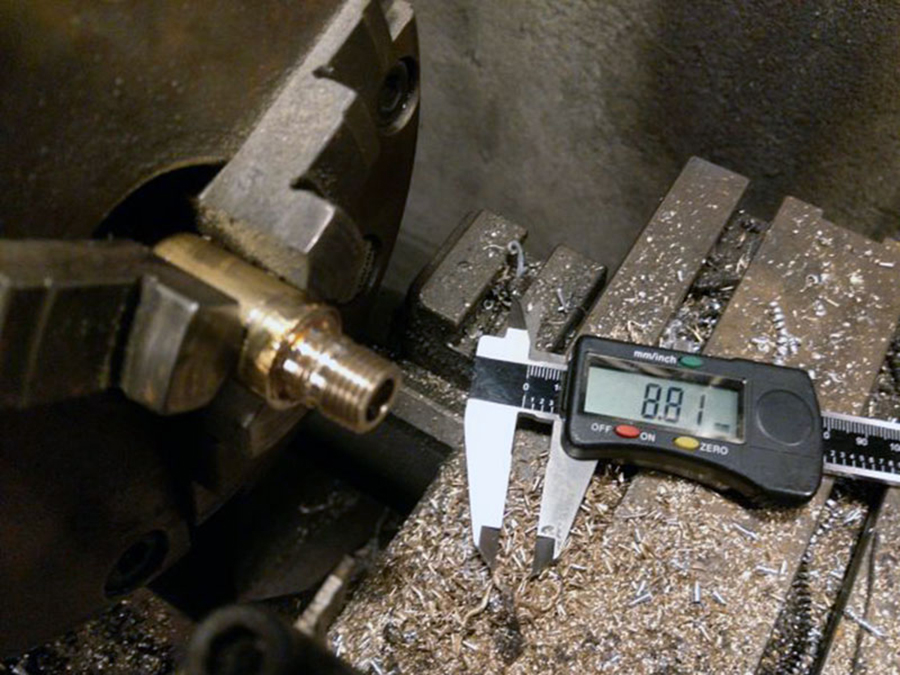

At the bottom you see the static mounting, in between the measuring bolt (with output cord), connected to the brake. The moment the brake is applied, it pulls on the bolt, and those forces are measured.

At the bottom you see the static mounting, in between the measuring bolt (with output cord), connected to the brake. The moment the brake is applied, it pulls on the bolt, and those forces are measured.

The brake is very important to dampen the extreme acceleration of the engine, making it easier to tune.

… and it ran like a charm again.

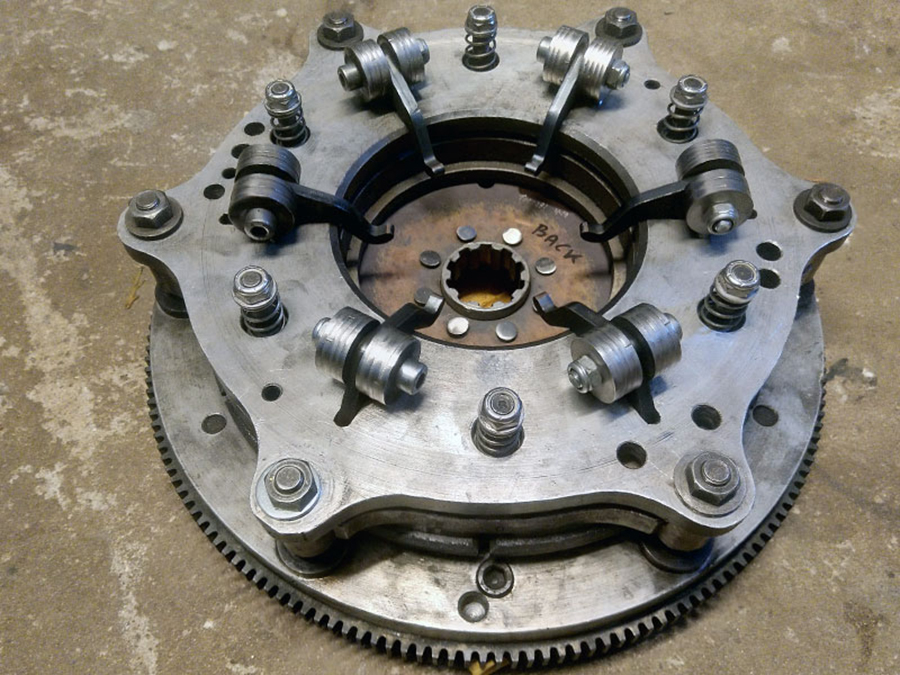

Speaking of ‘running like a charm’: March 31, 2021 was a great day! The new clutch did its job perfectly. Let’s move on to the next stage: adding NOS and boosting the horsepower!

And then, suddenly, there was that Moment of Reflection: will testing ever end, and what if I kill the engine during the test? I want to get on the road, damn it, and drive as long as I can and the law still allows me to. Carpe diem!

Made an important decision: disassemble, paintjob and riding. Tuning after that, as the CBX also had a stage 2 and 3 after the unveiling.

It was not easy to find a polisher for the many aluminum parts of my bike. I don’t have the hardware to polish properly myself, and I know from experience that it is 1. a craft and 2. makes an incredible mess without proper extraction.

It was not easy to find a polisher for the many aluminum parts of my bike. I don’t have the hardware to polish properly myself, and I know from experience that it is 1. a craft and 2. makes an incredible mess without proper extraction.

On a beautiful day in June 2021 I took the parts to Roelof van der Velde, owner of polijstbedrijf.com.

That was the reason I had them anodised immediately: during this electrolytic treatment, a rock-hard layer is created on the aluminum that is not sensitive to weather influences, with a beautiful silky gloss skin.

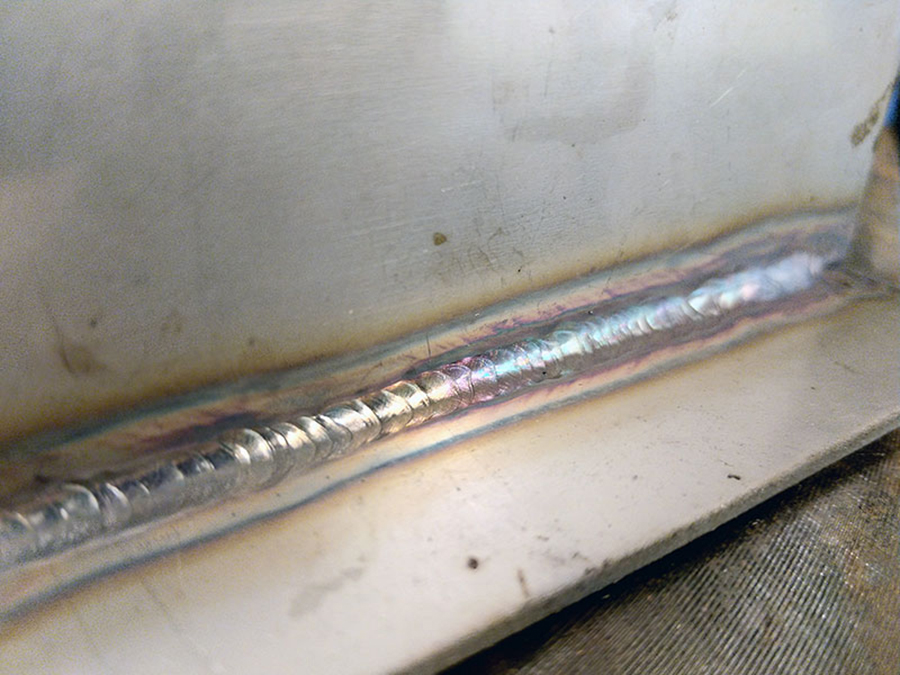

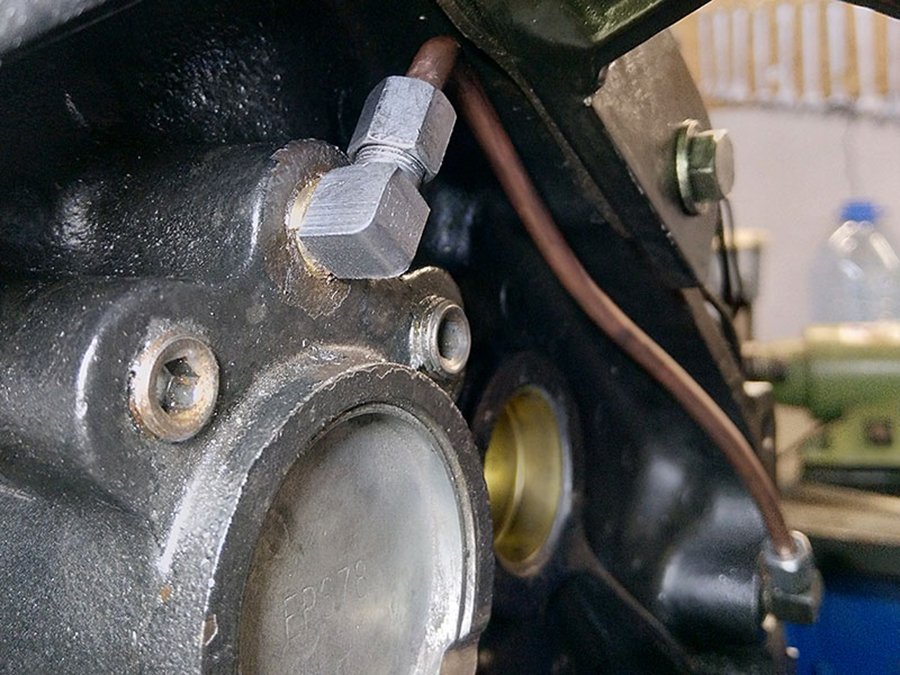

All was perfect, except for the lower triple tree: the weld spot on the side discolored bad and, even worse, the weld was leaking.

This caused brake fluid to leak out; this triple tree is used, just like the one on the CBX, as a transit and distributor for the front brake.

This caused brake fluid to leak out; this triple tree is used, just like the one on the CBX, as a transit and distributor for the front brake.

The misery that followed was incalculable: three different welders, including master-expert Willy Naves, tried to stop it leaking, but the aluminum had become so hot that it became porous; a lost case. :(

Filming The Real Deal. Again exciting because this phase can also undo all the work.

But: succesfull! :)

Niels also milled the valve covers. These presented him another challenge: the logo not in the covers but on it. This means that all the material around the logo had to be milled away so that the logo remains.

To prevent the covers to oxidate, I had them glass bead polished by Gacon. On the left you see owner Mike Gasseling.

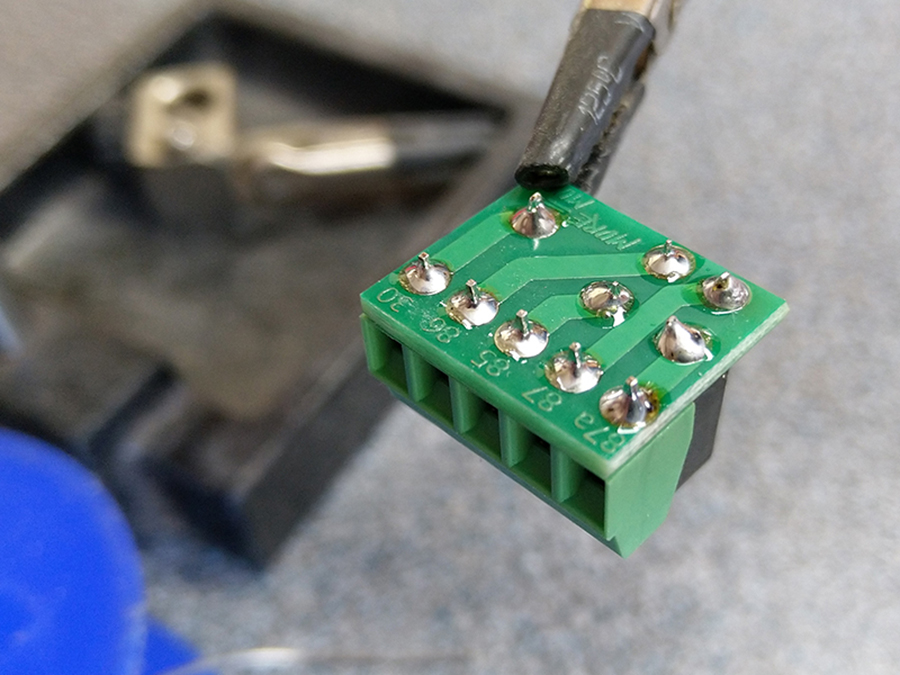

In Adobe Illustrator I drew printed circuit boards (PCB’s) and had them etched by VDR Electronics.

And so we arrive at the paintjob, of course a decisive phase for the appearance of the bike. Concept: coarse matt black combined with high-gloss black. Fortunately, painter Bart Colenbrander, aka Kustombart, likes a challenge because that’s what it was. Just like everything else in this project, but you know that by now.The video gives an impression of the coarse matt – gloss contrast.

So I drew the pattern in Illustrator and had the foil printed at blackfishgraphics.com.

I do a lot of lasercutting but didn’t know you can ingrave leather with it. This makes the lether matte, and that was the solution. The stitching was done by Miller Kustom Upholstery.

And now? Continue with finishing wiring, testing electronics, engine start, paintwork. Quite a lot.

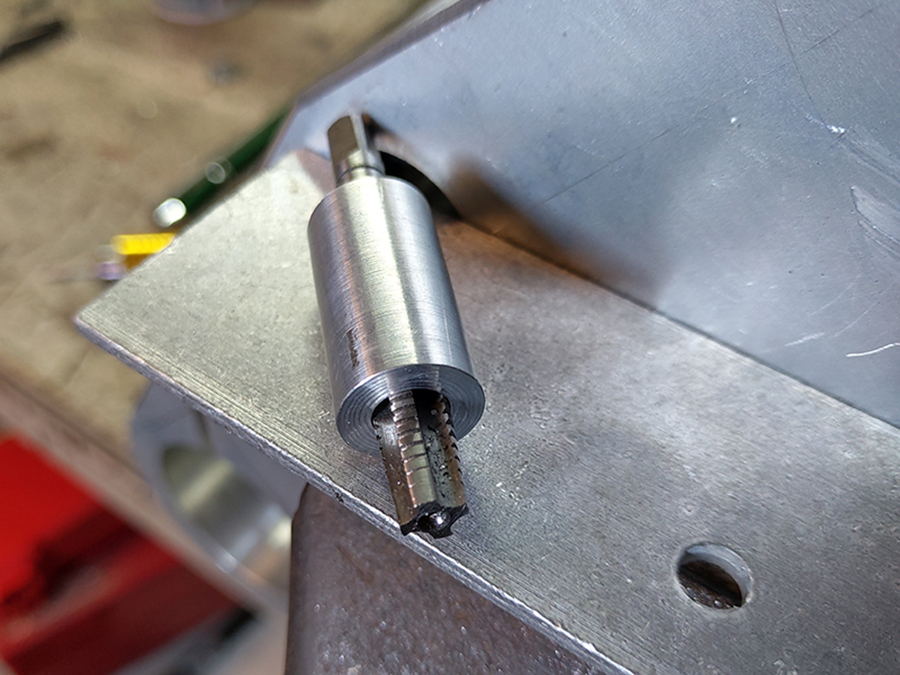

Also installed a new and important sensor, near the camshaft, so that the engine can now be injected sequentially. As a result, the amount of injected petrol can be selected per cylinder per speed, which will have a positive effect on the power.

Twelve updates … twenty years of building … all I can say: until the next one! ;)