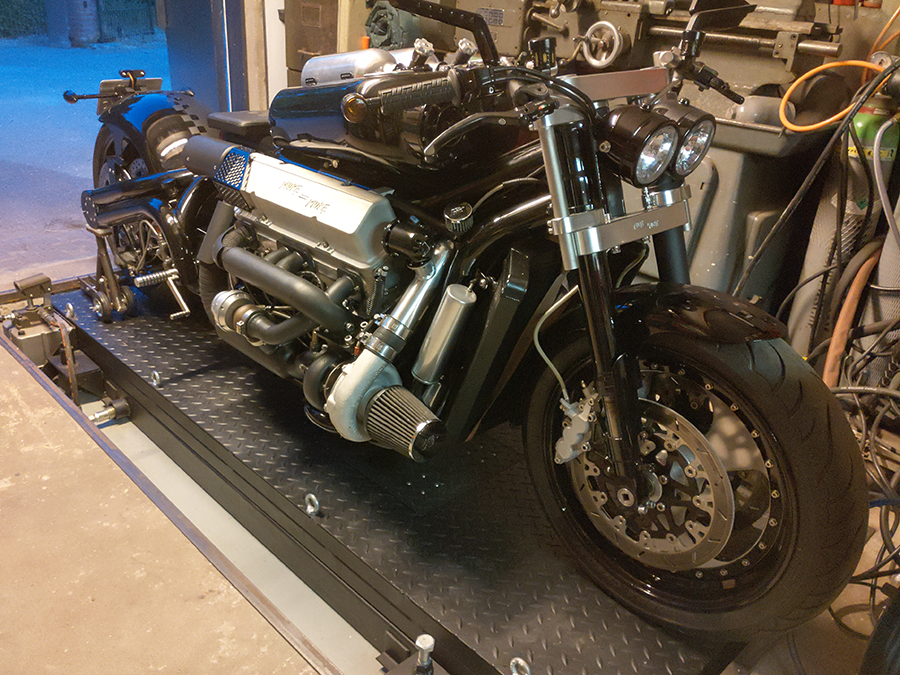

A lot has happened since update #12, November 2022. Time for… an update! This will be the last one about building the bike; after that focus is on the shows. :)

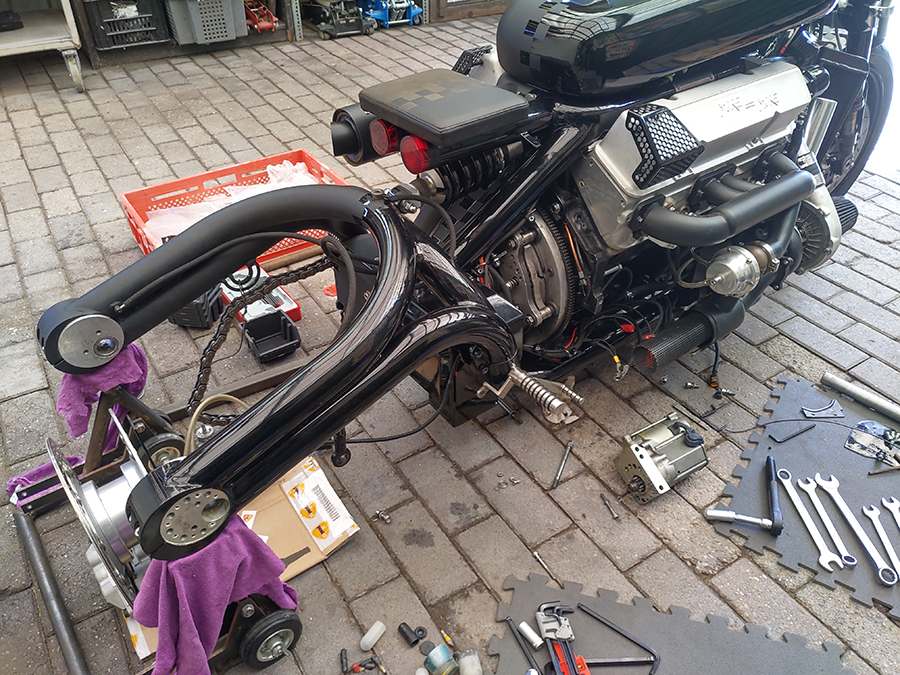

All heat-resistant ceramic coated parts (exhausts, heat shields and turbine housings) were re-blasted and coated.

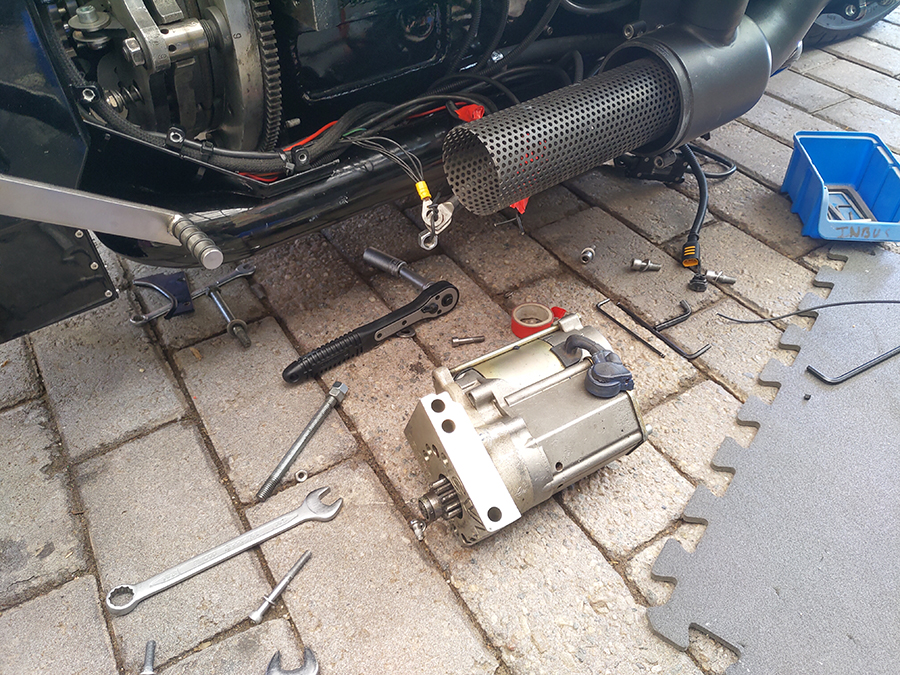

… without splitting the frame for the umpteenth time to remove the leaking front plate. I had forgotten a gasket around an empty coolant channel; I plugged this one. This won’t happen to me again.

… without splitting the frame for the umpteenth time to remove the leaking front plate. I had forgotten a gasket around an empty coolant channel; I plugged this one. This won’t happen to me again.

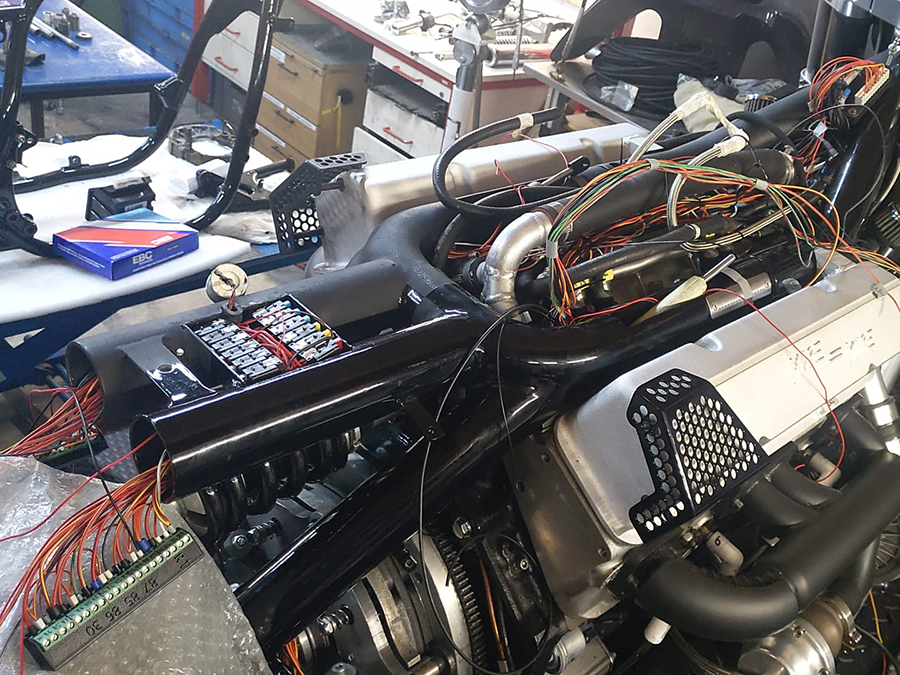

While I was at it I installed a camshaft position sensor. At a later time I can feed the data to the engine management system and use it for sequential fuel injection. This way I can specify the amount of fuel per cylinder at any rpm. I expect a lot from this in future tuning: efficiency and power gains.

… and low, fitted with a thick slab of trailer plywood. Solid, for times when the table is not in use.

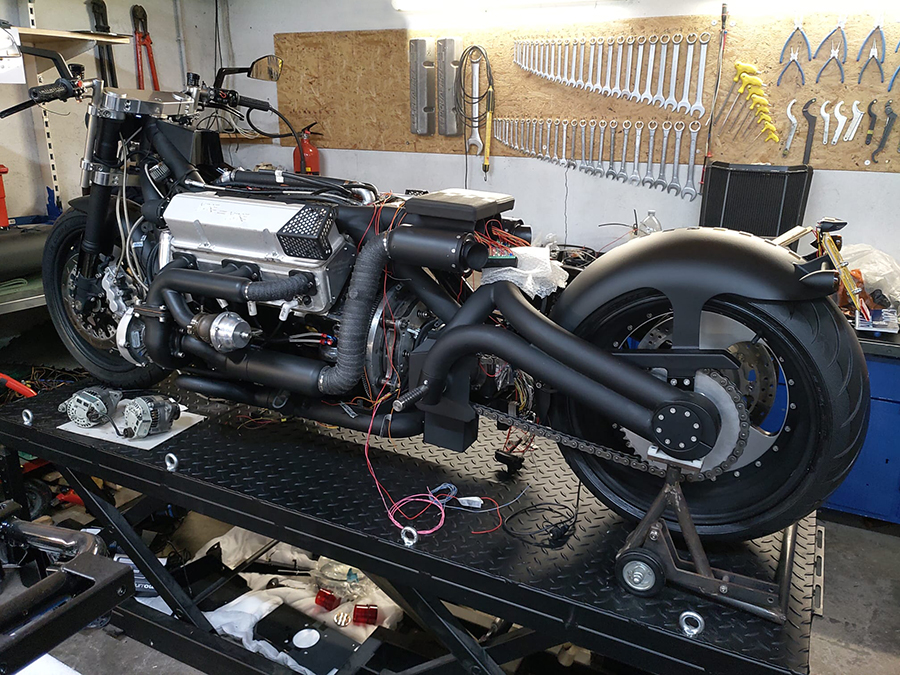

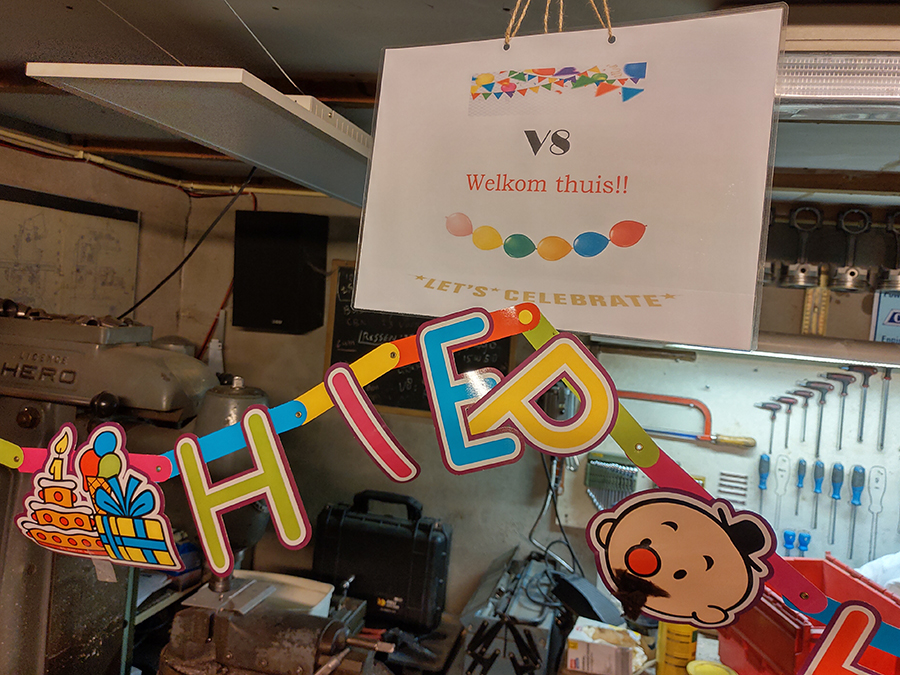

May 19, 2023: the move of the V8. A very special moment. Festive but also a bit sad and unreal, after so many years. The bike had lived with Peter since October 2011: no less than 11 years and 7 months.

May 19, 2023: the move of the V8. A very special moment. Festive but also a bit sad and unreal, after so many years. The bike had lived with Peter since October 2011: no less than 11 years and 7 months.

The workshop looked quite deserted. But a week later it was in full use again, as if the V8 had never been there. That’s good.

… because it moved to KustomBart in Apeldoorn, who put the finishing touches to the paintjob at his workshop.

Bart implemented the scheme of gloss and matte down to the smallest details. Here you see the new rear light, with integrated brake light and license plate light. Super small, and with full E(European) approval.

Bart and I celebrated the end of this phase with a good Döner, in a restaurant where atmosphere is apparently no priority.

The bike finally arrived home on June 4, 2023, for the first time since the build started. Frederiek had decorated the garage.

Like the rest a consistent mix of gloss and matt. Held in place by new leather straps, in style with the seat.

Unfortunately, the glass-beaded valve covers and turbos turned out to be very contagious to grease. They looked like sh*t in no time.

As always, at Gacon.

As always, at Gacon.

Post-apolcalyptic setting, such a blast cabin.

This time the blasting was immediately followed by drumming. This procedure, by company Dantech, causes the skin of the aluminum to be hammered shut and therefore impenetrable.

To ensure that the winch stops at the right time – not unimportant… – I installed an emergency stop switch at the front wheel.

To ensure that the winch stops at the right time – not unimportant… – I installed an emergency stop switch at the front wheel.

Peter Scheepers came by another morning to solve a minor problem with the m-Unit.

Peter Scheepers came by another morning to solve a minor problem with the m-Unit.

At the end of October I drove to Breezand and visited drag racing expert Joeri Woudenberg, founder and owner of Technomotion. He will assist me in the autumn when I start tuning again. I’m really looking forward to that.

Professional paint polisher Stijn Vervuurt took another good look at the paint. That didn’t work at first because it was too cold in the garage: the condensation after polishing caused unwanted striping on the paint.

Professional paint polisher Stijn Vervuurt took another good look at the paint. That didn’t work at first because it was too cold in the garage: the condensation after polishing caused unwanted striping on the paint.

I therefore had to raise the temperature in the garage considerably for a day. Not that easy this time of year, but it worked.

I therefore had to raise the temperature in the garage considerably for a day. Not that easy this time of year, but it worked.

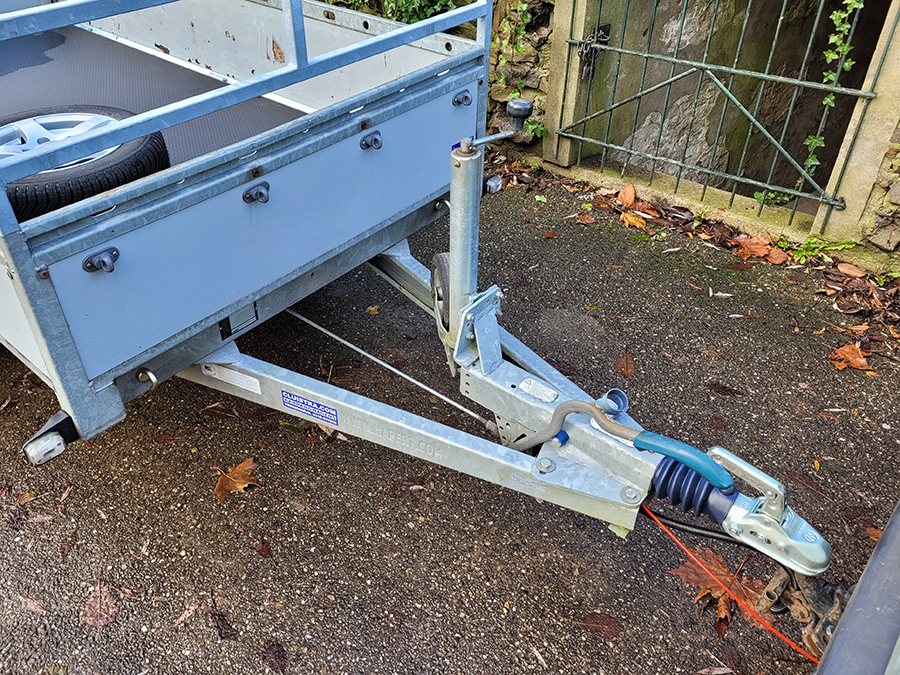

Because the total weight of my trailer plus bike turned out to be over 880 kilos – only 750 kilos is allowed… – I decided to convert it from unbraked to braked. So I bought a used braked trailer …

I was totally ready for the journalists and shows! See next report here.