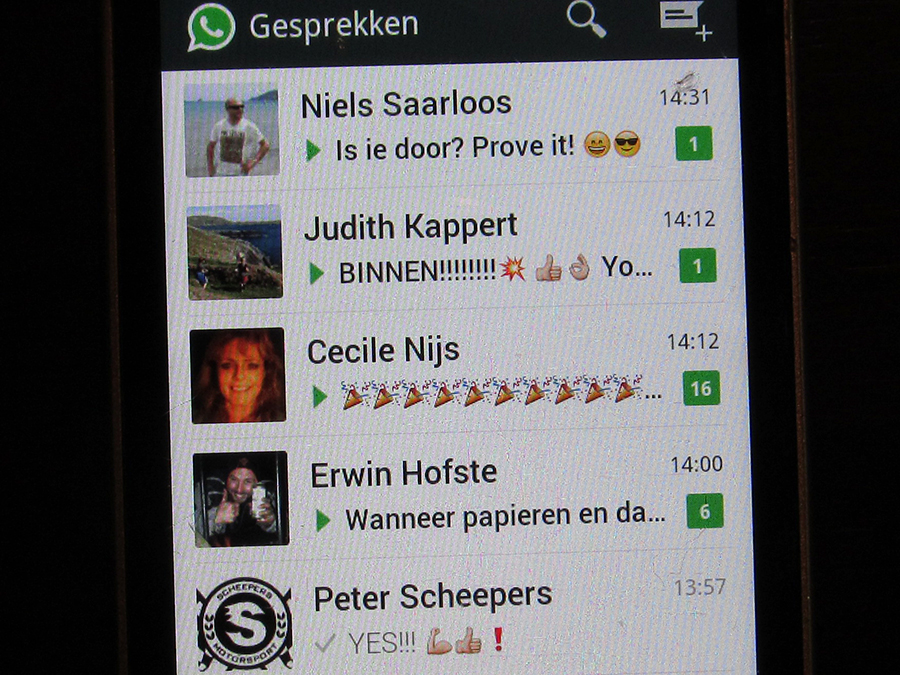

December 9 2014 I reached my main goal: 12 years and 3 months after I made the first sketch, the Dutch vehicle licensing authority RDW declared my V8 bike stree legal.

This success didn’t come out of nowhere. Update #7 tells the story: ‘The Way To and Past RDW’.

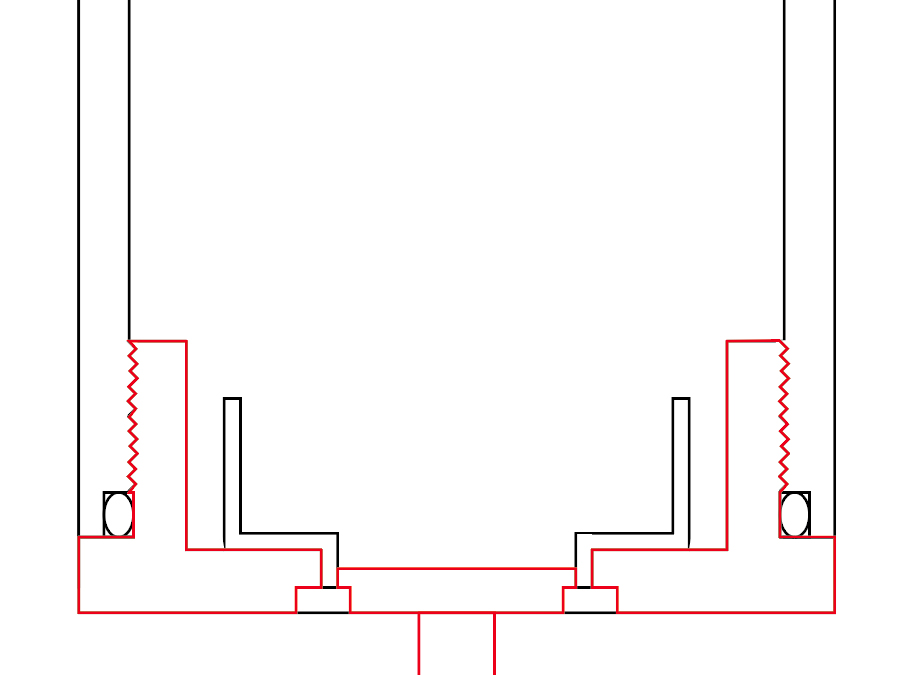

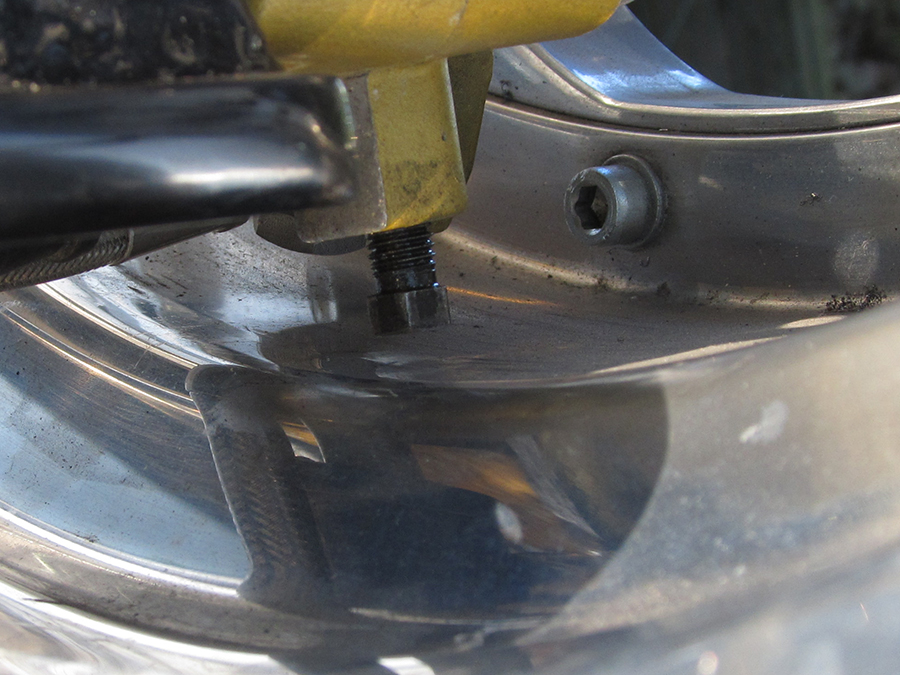

Starting small. The bike needed a so called identification plate. On it the name of the manufacturer and its VIN, vehicle identification number (source: 93/94/EEG-2006/27/EG). Well, I am the manufacturer so I put my name on it.

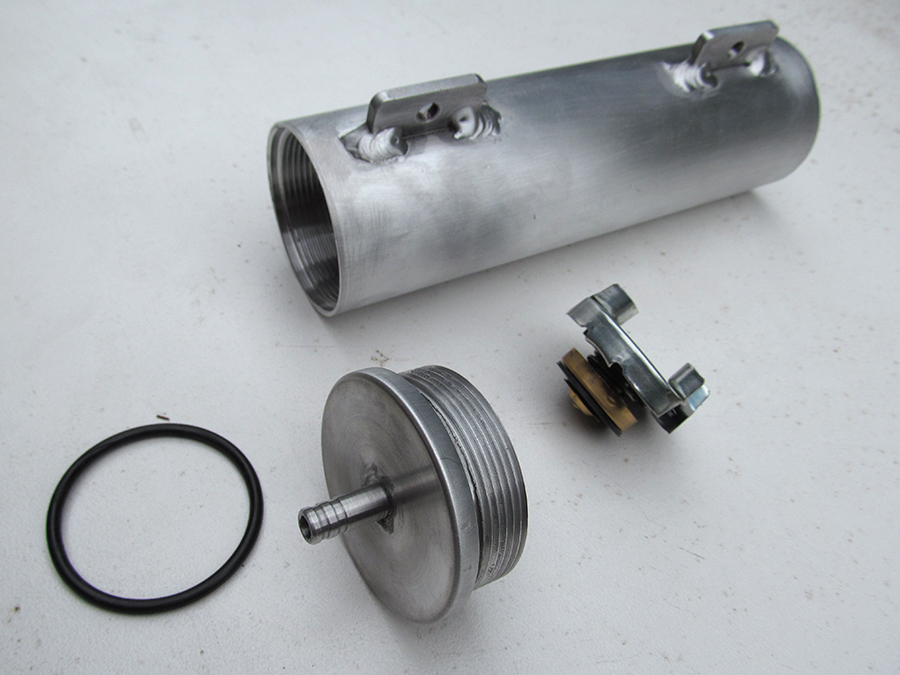

To solve it once and for all I invited expert Chris Janssen to help find a solution.

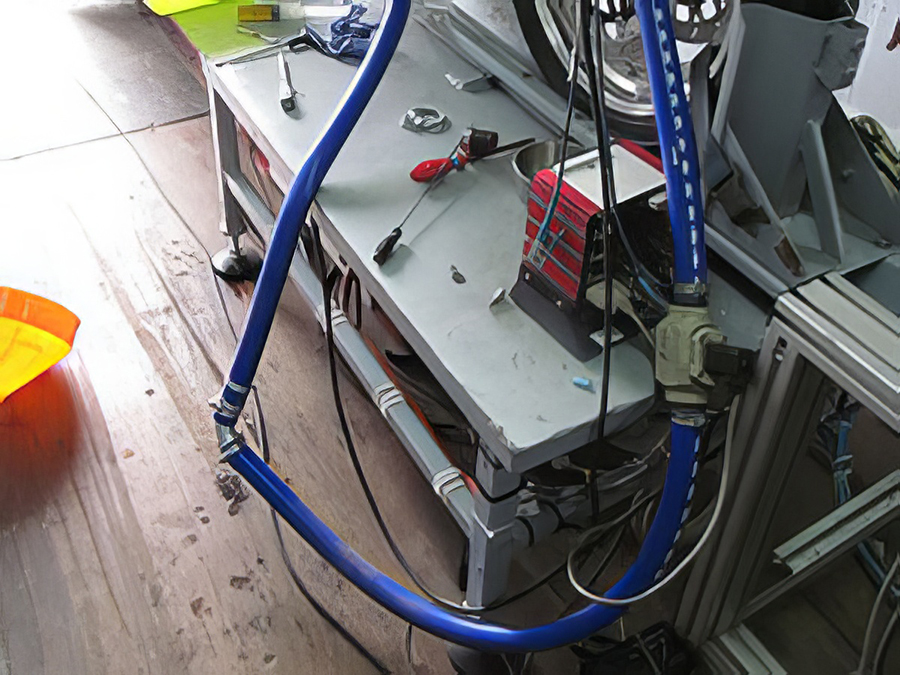

… and solved the problem by switching the polarity of the pump: 4 liters per minute got 46 liters per minute!

I was relieved and very annoyed at the same time: the wires were connected according to the pump’s manual. It might have been a production error, or an assembly error. Anyway: we found the problem fast, and furthermore we now know the real flow capacity in this configuration.

After that I explained testdriver Robert Begeman how to operate this bike. It not only weighs 530 kilos, it is very powerful, has just one gear, an exceptional position, a centrifugal clutch and a manual hydraulic clutch which operates exactly opposite a normal motorcycle clutch. Are you still there? ;)

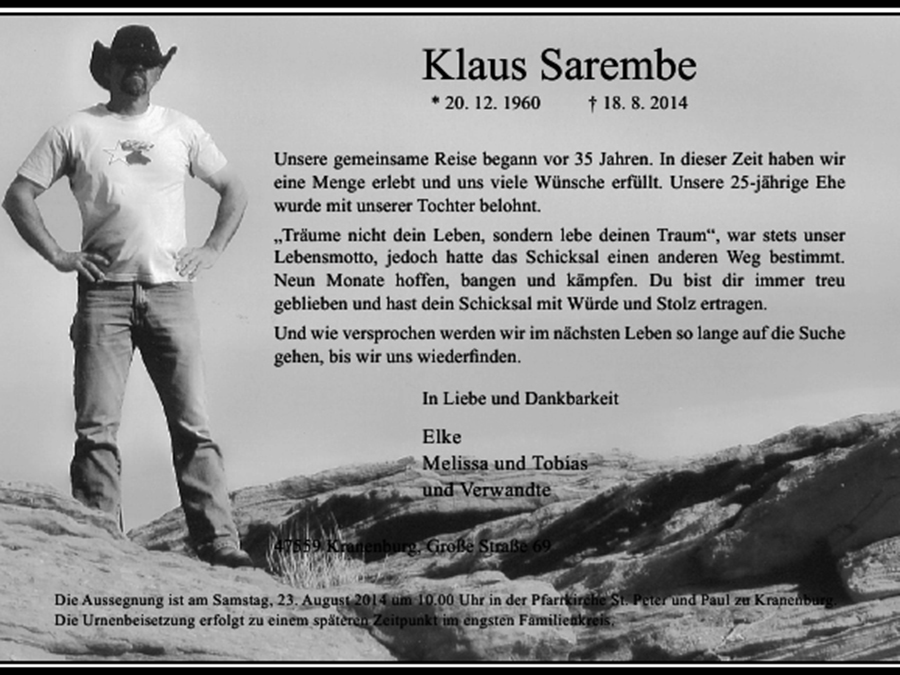

The test center in Lelystad has a huge oval track. Every new round Robert opened the throttle a bit more. For the first time Peter and I saw the potential of this bike. Every time he passed us it sounded like Nascar, ending acceleration with a loud whistle from the blow-offs. Wow! Klaus should have been there.

He tested no less than three quarters of an hour. Acceleration, brakes, sound, ground clearance, stabiltiy and tons of more demands. German bike builders often make fun of our RDW as their TÜV is said to be far more strict. Peter, bike builder ánd German, was very impressed though: he admitted that the tests were very thorough and exoteric.

We had a great lunch at a restaurant Italian Lounge. Best carpaccio ever!

We had a great lunch at a restaurant Italian Lounge. Best carpaccio ever!

What now? Ready? On the road? Don’t think so.

What comes next: water-methanolinjection (see previous report), NOS, performance test, disassembling for final paintjob, and finally on the road. It all fits in one sentence so this can’t take ages. But don’t pin me down: it’s still all R&D.